Hex Weld Lock Nuts With Flange

Send Inquiry

Hex weld lock nuts with flange are usually made from medium to high carbon steel or alloy steel. This makes them less prone to deformation and able to withstand high external pressure. The built-in flange increases the load-bearing area and distributes the pressure, thus preventing bending or breaking. We use high-strength materials to support the nuts to work for a long time in harsh environments.

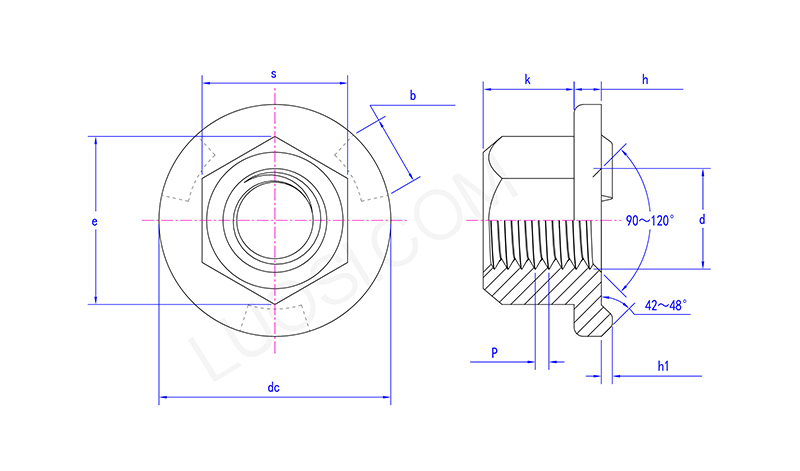

|

Mon |

M8 | M10 | M12 | M14 |

| P | 1.25 | 1.5 | 1.75 | 2 |

| h1 max | 1.1 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.9 | 1.1 | 1.1 | 1.1 |

| dc max | 22.5 | 26.5 | 30.5 | 33.5 |

| dc min | 21.5 | 25.5 | 29.5 | 32.5 |

| e min | 13.6 | 16.9 | 19.4 | 22.4 |

| h max | 2.75 | 3.25 | 3.25 | 4.25 |

| h min | 2.25 | 2.75 | 2.75 | 3.75 |

| b max | 6.1 | 7.1 | 8.1 | 8.1 |

| b min | 5.9 | 6.9 | 7.9 | 7.9 |

| k min | 9.64 | 12.57 | 14.57 | 16.16 |

| k max | 10 | 13 | 15 | 17 |

| s max | 13 | 16 | 18 | 21 |

| s min | 12.73 | 15.73 | 17.73 | 20.67 |

Application Scenario:

Hex weld lock nuts with flange get used a lot in industries that need threaded points that stay put and don’t loosen from vibration. They’re commonly used in structural steel frames, putting together heavy machinery, rail and transport systems, building ships, offshore platforms, and setting up process pipes. In these tough industries, these nuts work as reliable anchor points for bolts.

Advantages:

The hex weld lock nuts with flange gives a wider area to bear weight. That makes them grip better and not loosen from vibration as much as regular hex nuts. So they work well for cars, machines, and structural stuff that has to handle moving forces.