Heat treated stainless steel UN insert nut

Send Inquiry

Heat treated stainless steel UN insert nut parts are strong nuts with threads inside. They're used when you really need things to hold tight. These nuts have a bumpy outside surface. You press them into materials like metal, plastic, or composites to make a solid connection. The heat treatment makes the UN insert nut extra strong. That's why they're used in tough places like aerospace or car making, where parts face shaking and heavy use. The design helps things stay put and last longer, even when pulled or stressed hard.

Main perks

The main perks of heat treated stainless steel UN insert nuts are their really strong tensile strength and ability to resist corrosion. Heat-treating these nuts makes them hold up to 40% more weight than regular stainless steel nuts. The knurled (rough) outside keeps them from spinning once they’re installed. These nuts work well in tough spots,like places with saltwater, chemicals, or extreme heat/cold,without wearing out. For engineers, using these nuts means less worry about reliability. They cut down on maintenance costs and fewer assembly problems in structures or machinery.

What specific stainless steel grade is used for and why?

Our heat treated stainless steel UN insert nuts are made from 316L stainless steel. This austenitic type is really good at fighting corrosion, especially against chlorides. That makes these nuts a great choice for tough marine, chemical, and outdoor uses where they need to last a long time.

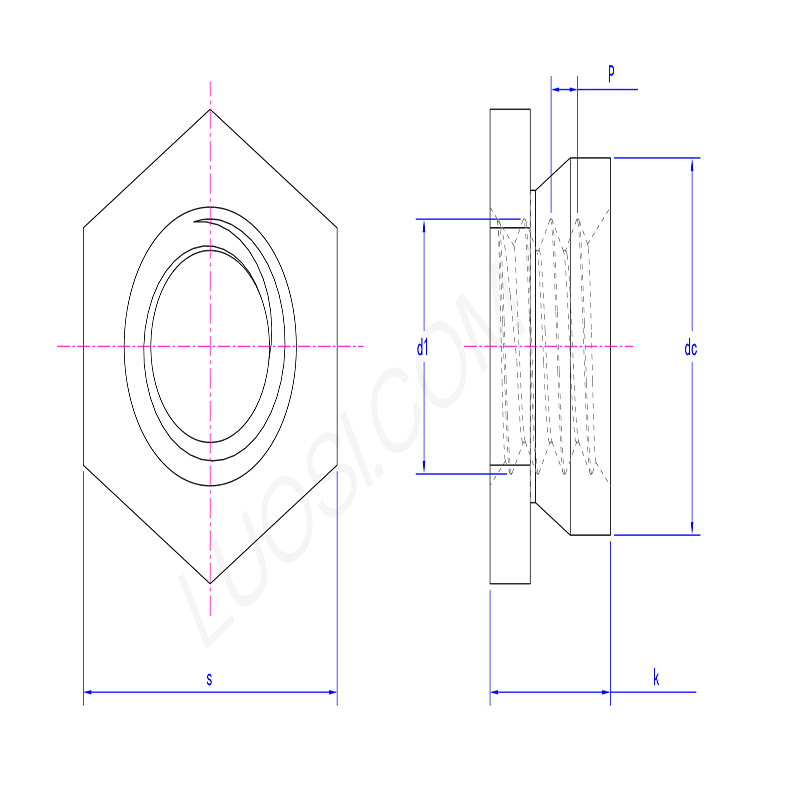

Product parameters

| Mon | 440-1 | 440-2 | 623-1 | 632-2 | 832-1 | 832-2 | 032-1 | 032-2 | 0420-3 | 0420-4 | 0420-5 |

| P | 40 | 40 | 32 | 32 | 32 | 32 | 32 | 32 | 20 | 20 | 20 |

| d1 | #4 | #4 | #6 | #6 | #8 | #8 | #10 | #10 | 1/4 | 1/4 | 1/4 |

| dc max | 0.171 | 0.171 | 0.212 | 0.212 | 0.289 | 0.289 | 0.311 | 0.311 | 0.343 | 0.343 | 0.343 |

| k max | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.06 | 0.09 | 0.12 | 0.151 | 0.182 |

| s | 0.188 | 0.188 | 0.25 | 0.25 | 0.312 | 0.312 | 0.343 | 0.343 | 0.375 | 0.375 | 0.375 |