Fork Joint

Send Inquiry

Fork joint is widely used in scenarios that require angle compensation and motion transmission, such as agricultural machinery suspension, engineering equipment joints, etc.

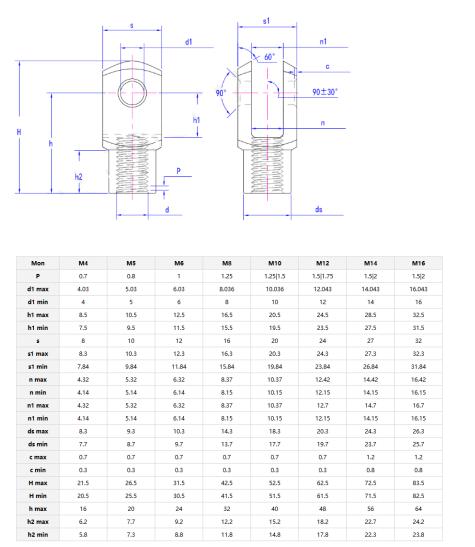

Details and parameters

The 120°symmetrical fork allows ±15°swing. The fork joint adapts to non-coaxial installation errors and avoids stress concentration in rigid connections. The material of this joint can be selected from 42CrMo alloy steel (high strength) or 316 stainless steel (corrosion resistance) to meet the needs of different working conditions.

Fork joints are critical in conveyor systems, connecting belt segments for smooth material transfer. Their forked design absorbs vibrations and lateral forces, reducing maintenance. In robotic arms, fork joints enable multi-axis movements for precise tasks like assembly line operations.

Market distribution

|

Market |

Revenue(Previous Year) |

Total Revenue (%) |

|

North America |

Confidential |

23 |

|

South America |

Confidential | 5 |

|

Eastern Europe |

Confidential |

19 |

|

Southeast Asia |

Confidential |

2 |

|

Oceania |

Confidential |

3 |

|

Mid East |

Confidential |

2 |

|

Eastern Asia |

Confidential |

15 |

|

Western Europe |

Confidential |

15 |

|

Central America |

Confidential |

5 |

|

South Asia |

Confidential |

6 |

|

Domestic Market |

Confidential |

5 |

Why Choose us

With experience in manufacturing fork joint in accordance with the DIN 71752-1994 standard, we provide pin-fork pairing tests (torque-swing angle curves) to ensure system-level performance;

We complete non-standard fork mouth designs (such as fork mouths with lubrication grooves and anti-slip locking structures) within 7 days, and support processing based on drawings.