Flush Mount Welding Flange Nut

Send Inquiry

In railway systems, flush mount welding flange nut are key for putting together tracks, bogies, and signaling gear. They don’t loosen up easily—even with constant movement and heavy loads—so that helps keep operations safe.

The flanged base on these nuts helps keep things stable and reduces wear on the parts they’re attached to. They’re mostly made from high-grade steel, so they can take a lot of pressure, along with heat changes and moisture.

They also meet all the specs for railway use—durable enough to work long-term in both passenger and freight trains. Basically, if you need nuts that stay tight and hold up in railway setups—where reliability matters a lot—these are a solid choice.

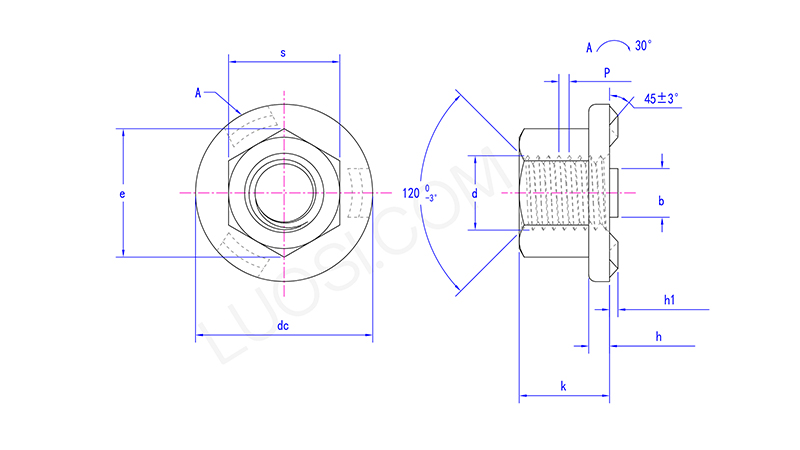

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| h1 max | 0.9 | 0.9 | 1.1 | 1.3 | 1.3 | 1.3 | 1.3 |

| h1 min | 0.7 | 0.7 | 0.9 | 1.1 | 1.1 | 1.1 | 1.1 |

| dc max | 15.5 | 18.5 | 22.5 | 26.5 | 30.5 | 33.5 | 36.5 |

| dc min | 14.5 | 17.5 | 21.5 | 25.5 | 29.5 | 32.5 | 35.5 |

| e min | 8.2 | 10.6 | 13.6 | 16.9 | 19.4 | 22.4 | 25 |

| h max | 1.95 | 2.25 | 2.75 | 3.25 | 3.25 | 4.25 | 4.25 |

| h min | 1.45 | 1.75 | 2.25 | 2.75 | 2.75 | 3.75 | 3.75 |

| b max | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 8.1 | 8.1 |

| b min | 3.9 | 4.9 | 5.9 | 6.9 | 7.9 | 7.9 | 7.9 |

| k min | 4.7 | 6.64 | 9.64 | 12.57 | 14.57 | 16.16 | 18.66 |

| k max | 5 | 7 | 10 | 13 | 15 | 17 | 19.5 |

| s max | 8 | 10 | 13 | 16 | 18 | 21 | 24 |

| s min | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 |

Product Advantages

The flush mount welding flange nut has a built-in flange that works like a washer—it gives a bigger bearing surface than regular nuts. This design lowers the pressure on the surface and keeps the connected materials from getting damaged.

These nuts usually come with either hexagonal or round bases. The surface might be rough (serrated) or smooth—depending on how much grip you need. They’re mostly made from carbon steel, stainless, or alloys, and often come with zinc or galvanized coatings to prevent rust.

Even though they’re pretty compact, they’re built strong and work with most welding setups. Basically, the built-in flange cuts out the need for a separate washer, and the materials/coatings make them hold up well—simple but effective for welding jobs.

Q:How is the corrosion resistance of your Flush Mount Welding Flange Nut?

A: Standard carbon steel flush mount welding flange nuts come with a zinc-plated coating, offering basic protection. For better corrosion resistance (suitable for harsh/outdoor applications), our stainless steel flush mount welding flange nuts are recommended as the preferred option.