Flush Finishing Countersunk Head Riveted Nuts

Send Inquiry

Flush Finishing Countersunk Head Riveted Nuts are of great significance in the aerospace industry. They can be used to manufacture connectors that are both robust and precisely matched, with typical applications being the connection parts between the external and internal structures of aircraft. Their main advantage lies in the fact that after installation, the surfaces remain smooth, which is beneficial for aerodynamic performance. This is very important because it helps to reduce drag. These rivets are also very reliable, which helps to maintain the structural stability of panels and service doors. These components must withstand extremely high pressures and repeated vibrations, and aircraft remain in this state throughout their usage. Therefore, they are indispensable for both commercial and military aviation applications.

Product Details

When manufacturing electronic casings, server racks and precision instruments, Flush Finishing Countersunk Head Riveted Nuts are a both aesthetically pleasing and low-key method of fixation. By installing these nuts, one can create sturdy threaded fixation points for panels and components - no hardware protrudes outward, which is extremely important for safety, appearance and efficient stacking of equipment. Using these nuts means there will be nothing stuck on them, and a neat and professional result can be achieved. As a result, sensitive electronic equipment can be properly fixed, facilitating maintenance, and the design can remain simple and smooth.

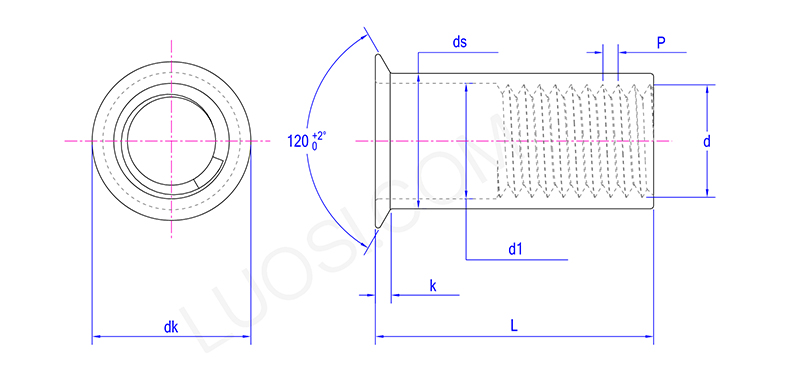

Product Parameters

| Mon | M3 | M4 | M5 | M6 | M8 | M10 | M12 |

| P | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

| ds max | 4.97 | 5.97 | 6.97 | 8.97 | 10.97 | 12.97 | 14.97 |

| ds min | 4.9 | 5.9 | 6.8 | 8.9 | 10.9 | 12.9 | 14.9 |

| d1 max | 4.12 | 4.92 | 5.72 | 7.65 | 9.35 | 11.18 | 13.18 |

| d1 min | 4 | 4.8 | 5.6 | 7.5 | 9.2 | 11 | 13 |

| dk max | 6.5 | 8 | 9 | 11 | 3 | 16 | 18 |

| k | 0.35 | 0.5 | 0.6 | 0.6 | 0.6 | 0.85 | 0.85 |

FAQ

Q: What is the primary installation process for your Flush Finishing Countersunk Head Riveted Nuts, and what tools are required?

A:Installing our Flush Finishing Countersunk Head Riveted Nuts is very simple, and you can complete the installation by operating from just one side. You need to use a specially designed rivet gun or hydraulic machine to pull the mandrel - during operation, the sleeve will deform and grip the workpiece from the back. This forms a permanent and strong thread.

These nuts are designed so that they can fit tightly into the pre-drilled countersunk holes, so after installation, the surface is flat, not protruding, and very smooth. This method is very suitable for use when only one side of the workpiece can be reached, making assembly much easier.