Double Studs Class 1

Send Inquiry

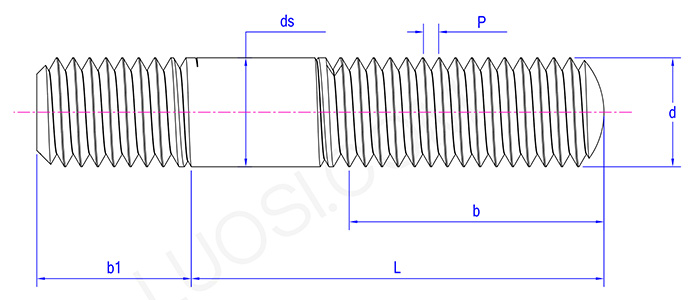

Double studs Class 1 is quite common in both industry and daily life. They are slender cylindrical in shape. Each stud is machined with regular external threads at both ends, with clear thread profiles and a smooth rod section in the middle.

Product Parameters

| Mon | M10 | M12 | M14 | M16 | M18 | M20 |

| P | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| ds max | 10 | 12 | 14 | 16 | 18 | 2.5 |

| ds min | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 20 |

| b min | 26 | 30 | 34 | 38 | 42 | 19.6 |

| b max | 29 | 33.5 | 38 | 42 | 47 | 46 |

| b1 min | 12 | 15 | 18 | 20 | 22 | 51 |

| b1 max | 13.1 | 16.1 | 19.1 | 21.3 | 23.3 | 26.3 |

Product Features

Double studs Class 1 is used for anchoring heavy machinery. Screw one end of the coarse thread deeply into the concrete ground anchor. Coarse threads can hold the concrete anchor sleeve very well. Fix the machine base onto the coarse thread at the other end. This setting enables the machine to vibrate on the studs without loosening the ground anchors below. This is a reliable method for fixing heavy-duty vibrating equipment.

These double studs can be used for calibration and adjustment. If the parts may move slightly or need fine-tuning, they can be very helpful. The nut will not be tightened too much on the thread, so it is easier to make fine adjustments after loosening the nut. You can fine-tune the parts to the ideal position and then finally tighten all the parts.

Because it has threads at both ends, it can be put to good use whether it is to connect two thick metal plates or to fix a thin part to a thick structure. It is easy to install and can be fixed in place without special tools. Save installation time and labor costs.

Double studs Class 1 is easier to maintain and disassemble. If your equipment needs to be disassembled frequently for cleaning or maintenance, they make the repair process easier. Even if the nut is slightly corroded or dirty, it can be easily removed. During the disassembly process, the possibility of the nut being rounded or the stud breaking is smaller.