Aluminium Alloy Self Clinching Flush Head Studs

Send Inquiry

Aluminium alloy self clinching flush head studs made of Aluminium alloy. The chromium and nickel in them form a protective oxide layer that stops rust, oxidation, and damage from tough conditions like saltwater, chemicals, or high humidity. These Aluminium alloy screws naturally hold up well structurally for a long time and need less maintenance, which makes them a solid choice for marine work, offshore setups, chemical processing areas, and coastal buildings.

Application

Aluminium alloy self clinching flush head studs made of Aluminium alloy are a must in aerospace. They’re used to fasten skin panels, fairings, and inside parts,anywhere surfaces need to be flush for aerodynamics and safety.

Same thing in marine setups: people use them for hull fittings, deck hardware, and superstructures that get hit with salty water all the time. The key is they go in flush, they’re strong, and they don’t corrode easy. That’s why these aluminium alloy screws are the go-to option in these tough environments where things have to hold up.

International Standards

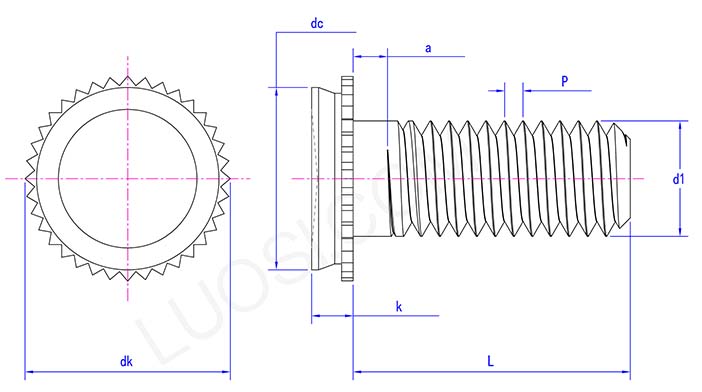

The aluminium alloy self clinching flush head studs comply with key international standards, primarily DIN 7337. This standard governs dimensions (head diameter, shank length/diameter), material properties, and performance characteristics. This ensures consistent quality, reliability, and interchangeability for industrial applications requiring a flush, permanent fastening solution.

Product parameters

| Mon | M3 | M4 | M5 |

| P | 0.5 | 0.7 | 0.8 |

| k max | 1.8 | 1.8 | 1.8 |

| dc max | 4.35 | 7.35 | 7.9 |

| dk max | 5.46 | 8.58 | 9.14 |

| dk min | 4.96 | 8.08 | 8.64 |

| d1 | M3 | M4 | M5 |

| a max | 1.6 | 1.6 | 1.6 |