Cup Head Rivets

Send Inquiry

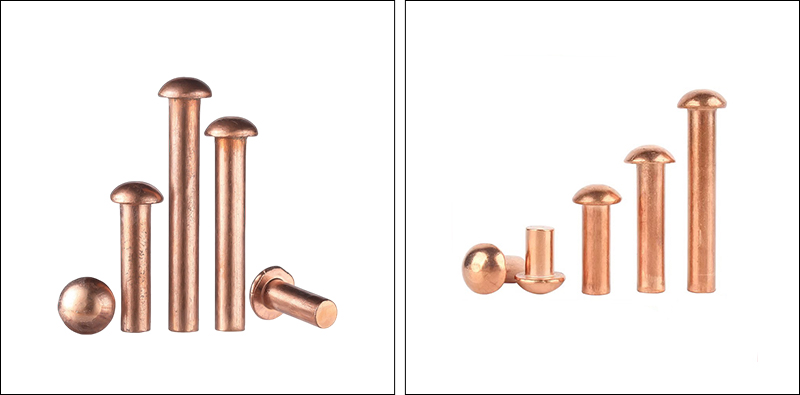

Cup head rivets are meant to stay put once you install ’em – they’re for jobs where you need connections that won’t budge. That rounded head shape? It helps spread weight more evenly and stops vibrations from rattling them loose. You’ll spot these in construction sites, car factories, or even airplanes – basically anywhere that needs heavy-duty sticking power.

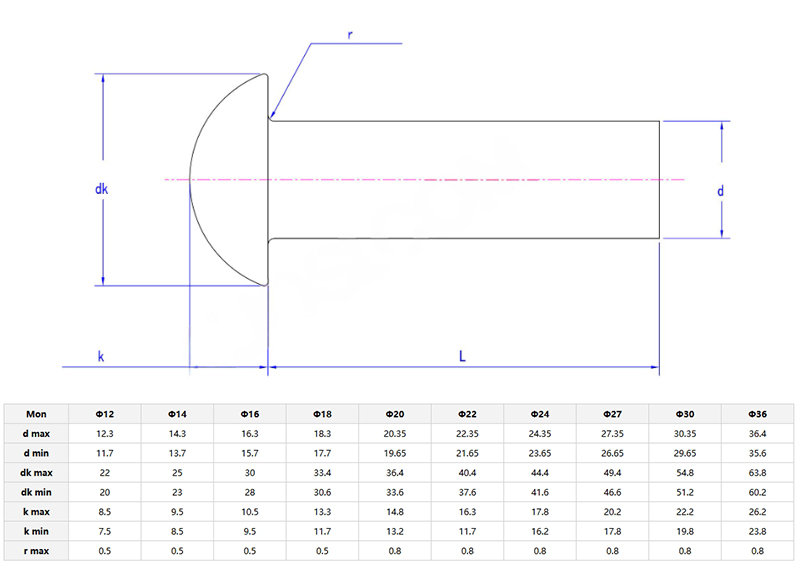

Product details and parameters

The design avoids weak spots, so they last longer even when things shift or weight changes. They come in various materials (steel, aluminum, etc.) and coatings, so you can match ’em to your project’s needs – whether it’s dealing with weather, chemicals, or just daily wear. Engineers dig ’em ’cause they’re straightforward, budget-friendly, and handle rough conditions without quitting.

Cup head rivets are built tough – they handle sideways forces better than most and don’t shake loose easily. That’s why folks use ’em for critical jobs where stuff can’t afford to fail. The rounded head sits flat once installed, so they won’t snag on parts in machines or outdoor setups. Unlike regular rivets, these work better with mixed material thicknesses. Got thin sheets or thicker metal? They’ll grip either without fuss.

Best part? You don’t need fancy tools – basic rivet guns get the job done. Saves time and cash on labor. Some versions come rust-proofed too, which helps if you’re dealing with salty air or chemicals. They’re checked off for stuff like aerospace and heavy machinery, so engineers dig ’em for meeting safety rules. Bottom line? If you need something that just works and lasts, cup head rivets are a solid pick.

FAQ

Q: What materials are cup head rivets typically made from, and how do they impact performance?

A:They are usually made from three materials: stainless steel, aluminum, or carbon steel. Let me break it down. Stainless steel ones? They’re your go-to if you’re dealing with water or outdoor stuff – like near the ocean – ’cause they don’t rust easily. Aluminum rivets are lighter and work okay for electrical jobs since they conduct decently. Carbon steel’s the tough guy here – pick these if you need serious strength for heavy-duty work. What material you choose basically decides how long they’ll last, how much weight they can take, and whether they’ll survive your work environment. Pro tip: Think about where you’ll use them first – like, is it super wet or crazy hot? That’ll help you pick. Oh, and if things get rough, ask about zinc coatings (they call it galvanizing). It’s like armor for your rivets.