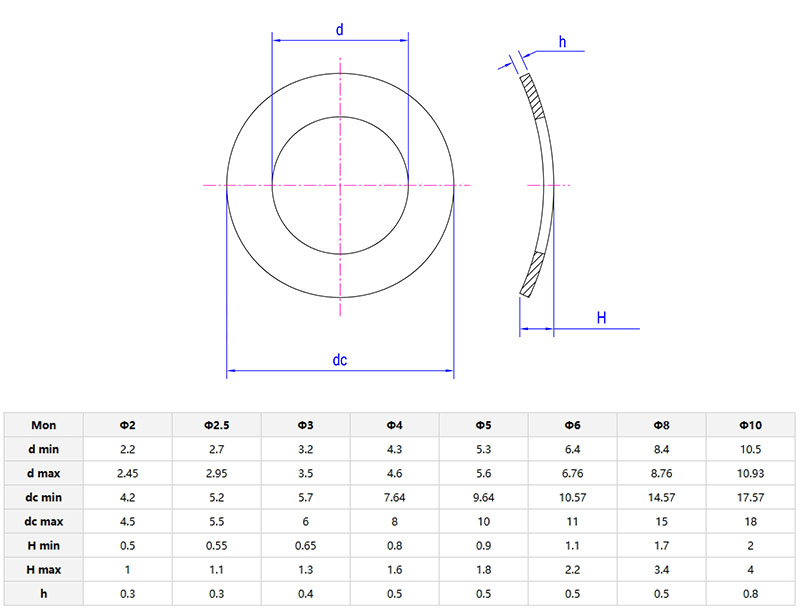

Compression Spring Washer

Send Inquiry

Compression spring washers are cone-shaped pieces used in bolted connections. They’re made to add some give along the bolt’s axis and keep tension tight. Their curved shape lets them act like small springs, handling vibrations, heat expansion, or loosening from moving loads.

Unlike flat washers, these curved ones keep steady pressure between parts, so the connection stays strong over time. You’ll see compression spring washers a lot in machines, cars, and industrial gear where stopping vibrations is key. The way they’re shaped spreads the load evenly, which means less stress on bolts and nuts.

Basically, if you need to keep tension steady even when things are shaking or conditions change, these washers are a must.

Advantages

The main benefit of compression spring washers is that they stop fasteners from coming loose on their own in places with a lot of vibration. They work like springs, absorbing shocks and keeping the clamping force tight. That means less time when machines are down and less money spent on maintenance.

Plus, the compression spring washers are cheaper than complicated locking systems. They offer a simple solution that’s tough and reliable. They don’t weigh much, so they don’t make assemblies bulky. That’s great for situations where space is tight.

You can get them in different materials and coatings, so they work in all kinds of environments,from salty marine setups to hot industrial machines.

Materials

Q: What materials are compression spring washers usually made from, and how do they affect rust resistance?

A: Compression spring washers are usually made from three things: stainless steel (like 304 or 316, which are good against rust), carbon steel (often dipped in zinc or other coatings), or alloys like Inconel for really hot places. What you pick here decides if they’ll rust or hold up over time.

Stainless steel works better in wet or chemical-heavy spots. Carbon steel needs that zinc coating to avoid rusting. If you’re using them near saltwater, super humid areas, or harsh chemicals, go with 316 stainless or ones treated to fight rust. Just tell us where they’ll be used, and we’ll sort out the best material for your compression spring washers.