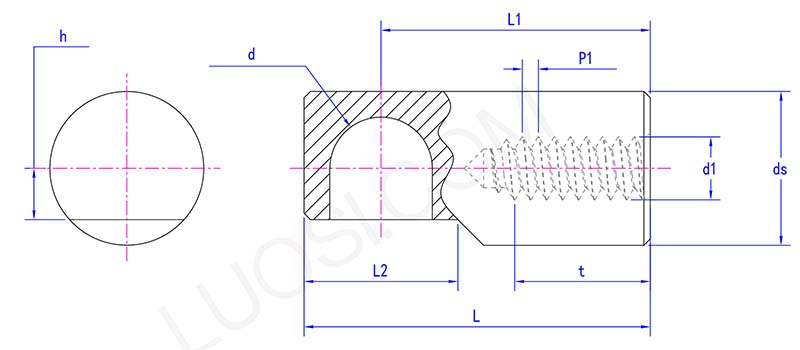

Clevis Type I Connector

Send Inquiry

Clevis type I connector often get surface treatments like nickel plating (without electricity), zinc coating, or anodizing. These treatments help them resist rust, reduce friction, and give them a finished look.The tips are polished or ground to be extremely smooth, reducing friction during movement. For harsh environments such as high temperatures or high levels of chemicals, we add special coatings such as Teflon (PTFE). All these treatments make the pins last longer and work reliably, even when used in extreme conditions.

Mon

Φ8

Φ10

Φ12

d max

8.058

10.058

12.07

d min

8

10

12

ds

12

14.5

17.5

d1

M5

M6

M8

h

4

5

6

L

42

47.5

53

L1

36

40

44

t

25

27

29

L2

12

14.5

17.5

P1

0.8

1

1

Dimensions

Clevis type I connector come in sizes from as thin as 2mm to chunky 50mm across, and they can go up to 300mm long if needed. The ball tips match standard bearings or bushings you’d find in most gear. They’re built super precise (like±0.01mm in some cases) so they fit parts without jamming.

For putting them in, threaded ones (think M4 to M20 sizes) screw straight into drilled holes.

If you need a different shape, such as a stepped, conical, or any shape required by the project, Xiaoguo® factory can customize it. You only need to provide the corresponding shape and parameters.

In extreme temperatures or harsh environments

Clevis type I connector made from heat-proof alloys or ceramics hold up in crazy temps,think freezing cold (-50°C) to oven-hot (500°C). Stainless steel ones are go-tos for wet or rusty spots, like boats or chemical plants. Ceramic pins won’t rust even in super hot furnaces. Slap on some moly grease or similar coatings, and they handle rough, high-friction jobs way better.

These pins get tested like crazy to make sure they stay precise and hold weight, even when things heat up or shake. Basically, they’re built to not quit when the going gets tough.