Clevis I Type Connectors

Send Inquiry

For food-grade or marine uses, high-quality clevis I type connectors are made from AISI 304/316 stainless steel. For heavy-duty jobs, alloy steels like 4140 or 4340 are used,these are hardened to 45-50 HRC to handle tough loads. In aviation, titanium (Grade 5) versions are chosen because they offer a strong balance of strength and light weight. For industrial furnaces with extreme heat, there are ceramic-coated options. Material certifications like RoHS and REACH make sure they meet global safety and environmental rules.

Inspection And Maintenance

To make clevis I type connectors last longer, clean off dirt and debris regularly with gentle solvents (not the rough kind). Put lithium grease on the ball tips to keep them moving smoothly. During regular check-ups, look for cracks or tiny pits on the surface. When installing, don’t tighten them too much,you might damage the threads. Store them in dry places to avoid rust. If a pin is worn out or doesn’t fit properly anymore, replace it to keep your system working right.

Quality Certifications

As a professional Chinese manufacturer, Xiaoguo® provides clevis I type connectors that comply with standards such as ISO 9001 (quality management), ISO/TS 16949 (automotive) or AS9100 (aerospace).Certifications such as RoHS and REACH ensure compliance with environmental and safety regulations.We can provide Material Test Reports (MTR) and hardness/load test documentation to support performance claims.For medical or food-grade use, FDA-approved materials are used to ensure they are non-toxic.Be sure to check that the certification complies with regulations in your industry to avoid any operational issues.

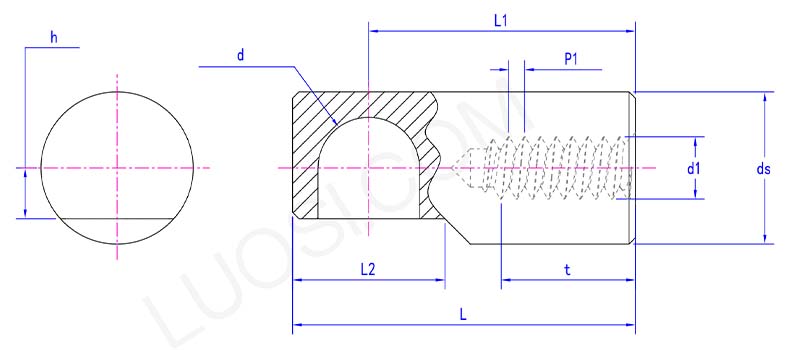

Mon

Φ8

Φ10

Φ12

d max

8.058

10.058

12.07

d min

8

10

12

ds

12

14.5

17.5

d1

M5

M6

M8

h

4

5

6

L

42

47.5

53

L1

36

40

44

t

25

27

29

L2

12

14.5

17.5

P1

0.8

1

1