Clevis Connectors

Send Inquiry

Clevis connectors have round holes that can be inserted with pins, bolts or other fasteners that match the holes. The material can be selected from corrosion-resistant stainless steel, carbon steel, titanium alloy, etc., depending on the specific usage scenario and needs.

They can have special features added, like inner channels for lubrication, magnetic tips, or sensors built right in for smart machines. Some use two materials,steel in the middle with a polymer coating outside,to cut down on noise. Their tips can be shaped specially, like oval or flattened, to solve tricky alignment issues.

Quality Standards

Clevis connectors follow quality standards like ISO 9001, AS9100, and IATF 16949, which help ensure they’re good for cars, planes, and medical devices. Being RoHS compliant means they don’t have harmful substances. Independent labs test them,for example, they can handle 1 million cycles with a 10kN load to prove they resist fatigue.

The paperwork that comes with them includes material test reports (MTRs) and 3D CAD models, which make it easier to use them in digital design processes.

Features and cost

Compared to standard pins, the rounded tip of the clevis connectors effectively reduces wear and allows components to operate more smoothly in pivoting mechanisms. Although the initial cost is 15% to 30% higher, they can significantly reduce long-term maintenance requirements and equipment downtime in systems with frequently moving parts. For example, in conveying systems, this design also reduces surface wear, thereby extending component life.

Whether they’re cost-effective depends on how important the application is. Industries that need precision, like aerospace, get the most benefit from their better performance, even though they’re more expensive.

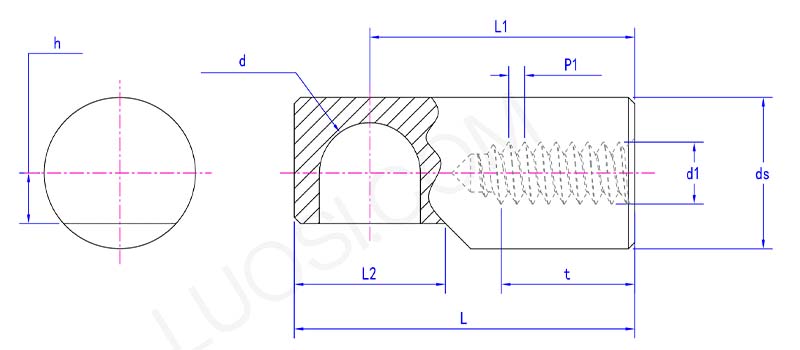

|

Mon |

Φ8 |

Φ10 |

Φ12 |

|

d max |

8.058 | 10.058 | 12.07 |

|

d min |

8 | 10 | 12 |

|

ds |

12 | 14.5 | 17.5 |

|

d1 |

M5 | M6 | M8 |

|

h |

4 | 5 | 6 |

|

L |

27 | 32.5 | 38 |

|

L1 |

21 | 25 | 29 |

|

t |

10 | 12 | 14 |

|

L2 |

12 | 14.5 | 17.5 |

|

P1 |

0.8 | 1 | 1 |