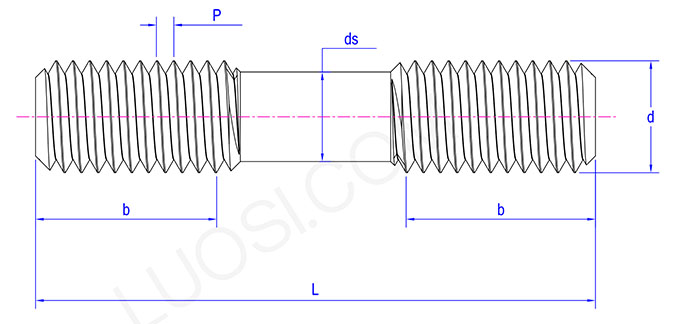

Clamping Type Double End Studs

Send Inquiry

The main function of clamping type double end studs is to tightly clamp two objects together to achieve a stable connection. It is a metal rod with threads at both ends and a smooth part in the middle. It comes in a variety of specifications and has extremely high flexibility.

Product parameters

| Mon | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 |

| P | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 |

| ds | 1.74 | 2.21 | 2.86 | 3.55 | 4.48 | 5.35 | 7.19 |

Features

Double ends anchor bolts can lock the bearing to ensure no clearance. Screw the bearing into the bearing housing, slide the bearing through the stud, and tighten both side nuts to 120 N·m. The double clamping device can prevent micron-level offset during 20,000 RPM operation. A loose spindle can destroy a workpiece worth $5,000 within minutes.

Clamping type double end studs can form adjustable connections. Screw both ends into the flange or plate, and then tighten the nuts to precisely connect the components together. It enables you to align mismatched pipes or mechanical supports without applying external force to the parts.

Double ended anchor bolts can withstand thermal expansion. When the metal heats up, slightly loosen one end while keeping the other end clamped tightly. They can prevent boilers or exhaust manifolds from warping. They can be firmly locked. Both ends are tightly adhered to the surface with double nuts, which can better prevent loosening in the pump base or conveyor frame than single bolts.

One of the characteristics of clamping type double end studs is that the threads at both ends are symmetrical, with the same length and specification. Thus, when clamping objects, the force on both sides is uniform and the connection is more stable. The second feature is its strong load-bearing capacity. Due to its structural design and the materials selected, it can withstand considerable pressure and tensile force.