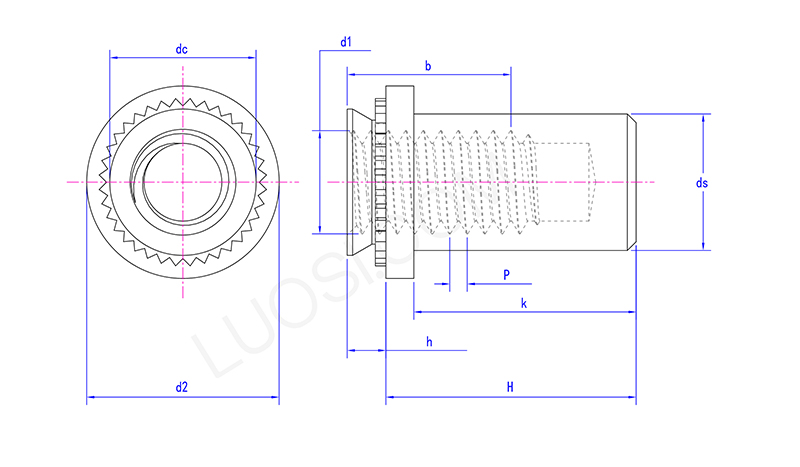

Carbon Steel Sealing Clinching Nut

Send Inquiry

Carbon steel sealing clinching nuts are a type of fastener used for connecting thin plates or sheet metals. They are made of carbon steel, tempered and quenched to increase hardness, and the surface is galvanized or otherwise made corrosion-resistant.

The sealing clinching nut is pretty straightforward,you can use standard pneumatic or hydraulic clinching tools. Here’s how it works: first, put the nut into a pre-punched hole, then use a punch and die set to apply pressure. The die presses the sheet metal around the nut’s clinch collar, forming a solid mechanical lock in one quick step.

| Mon | M3-1 | M3-2 | M4-1 | M4-2 | M5-1 | M5-2 | M6-1 | M6-2 |

| P | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 0.8 | 1 | 1 |

| ds max | 3.84 | 3.84 | 5.2 | 5.2 | 6.35 | 6.35 | 8.75 | 8.75 |

| dc max | 4.2 | 4.2 | 5.38 | 5.38 | 6.33 | 6.33 | 8.73 | 8.73 |

| b min | 5.3 | 5.3 | 7.1 | 7.1 | 7.1 | 7.1 | 7.8 | 7.8 |

| h max | 0.91 | 1.38 | 0.97 | 1.38 | 0.97 | 1.38 | 1.38 | 1.38 |

| H max | 9.85 | 9.85 | 11.45 | 11.45 | 11.45 | 11.45 | 14.55 | 14.55 |

| H min | 9.35 | 9.35 | 10.95 | 10.95 | 10.95 | 10.95 | 14.05 | 14.05 |

| k max | 8.5 | 8.5 | 9.8 | 9.8 | 9.8 | 9.8 | 12.7 | 12.7 |

| d2 max | 6.6 | 6.6 | 8.2 | 8.2 | 9 | 9 | 11.35 | 11.35 |

| d2 min | 6.1 | 6.1 | 7.7 | 7.7 | 8.5 | 8.5 | 10.85 | 10.85 |

| d1 | M3 | M3 | M4 | M4 | M5 | M5 | M6 | M6 |

Specifications:

Carbon steel sealing clinching nuts are defined by key measurements: thread size (like M4, M5, M6, or 1/4"-20), clinch collar diameter, total height, sealing washer dimensions, and the sheet thickness range they work with (both min and max). You can get them in standard metric or imperial threads.

Their clinch strength (how well they resist being pushed out or twisted off) is tested against industry standards (think ISO, DIN, IFI). Picking the right size is a big deal,it makes sure the seal holds and the nut is strong enough for the job.

Recommended installation steps:

To install the carbon steel sealing clinching nut, you need a specialized clinching tool and die set that exactly matches the nut’s size. First, put the nut into a pre-punched hole in the sheet metal. Then the tool applies controlled pressure, which makes the nut’s pilot and knurl sink into the surrounding metal. This cold-forming process locks the stainless steel nut in place for good and at the same time, it squishes the built-in sealing washer against the panel. That’s how it creates the leak-proof seal that makes these nuts unique.