Carbon Steel Hexagonal Rivet Nut Column

Send Inquiry

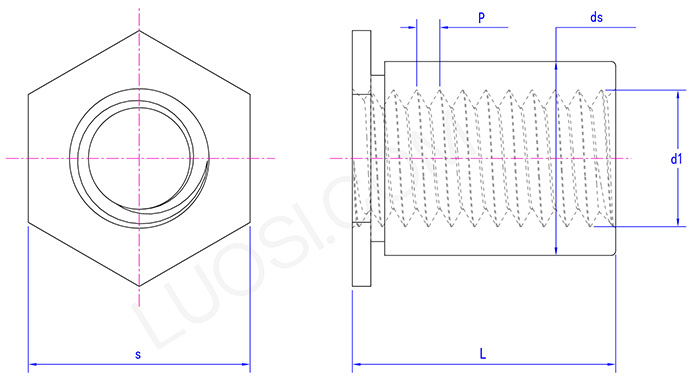

The carbon steel hexagonal rivet nut column is a specialized fastener with internal threads. It’s made for creating tough, load-bearing threads in thin or brittle materials where you can’t use welding. Acting as a permanent anchor, it has a hexagonal body that stops it from spinning during installation. The hollow column collapses outward when you use a rivet nut tool, forming a solid bulge on the blind side.

This rivet nut column gives you a strong female thread (usually metric or UNC) in panels, extrusions, or sheet metal setups. Compared to tapping threads directly into the base material, it way boosts pull-out strength.

Product parameters

| Mon | M2.5 | 6M2.5 | M3 | 6M3 | M3.5 |

| P | 0.45 | 0.45 | 0.5 | 0.5 | 0.6 |

| ds max | 4.2 | 5.39 | 4.2 | 5.39 | 5.39 |

| ds min | 4.07 | 5.26 | 4.07 | 5.26 | 5.26 |

| s max | 5 | 6.6 | 5 | 6.6 | 6.6 |

| s min | 4.6 | 6.2 | 4.6 | 6.2 | 6.2 |

| d1 | M2.5 | M2.5 | M3 | M3 | M3.5 |

Advantages

The main upsides of the carbon steel hexagonal rivet nut column are its great strength for its weight and how cost-effective it is. The hexagonal shape stops it from spinning at all during installation or when it’s in use, which is key for keeping threads aligned when there’s vibration or torque.

Compared to a lot of other options,especially in thin metals,this rivet nut column has way better pull-out and torque-out resistance. Installing it is pretty quick and only needs access from one side, so it’s perfect for retrofitting or in enclosed structures. Its tough carbon steel build means it works reliably in tough mechanical setups.

Corrosion resistant

The standard carbon steel hexagonal rivet nut column is made of uncoated carbon steel, which has pretty limited rust resistance on its own. It works okay in dry, indoor setups where there’s not much moisture. But if you’re using it outdoors or in a corrosive environment, you’ll want to go for versions that have electro-galvanized, hot-dipped galvanized, or zinc-nickel plating. These coatings really boost the rust protection and make the rivet nut column last a lot longer.