Aerodynamic Countersunk Head Riveted Nuts

Send Inquiry

We offer quantity-based discounts to help you save money when purchasing Aerodynamic Countersunk Head Riveted Nuts. Usually, if you place an order for more than 50,000 pieces at one time, you will receive a tiered discount - that is, the more you order, the better the discount will be.

If you have a large project and need a specific price, our sales team can create a customized quote for you. We value building long-term partnerships, so for regular orders of these nuts, we also offer more favorable terms. This way, you can get the maximum return on your investment.

Ideal Rust Protection

The Aerodynamic Countersunk Head Riveted Nuts usually have a natural metal surface treatment effect, such as the common aluminum or steel surfaces. However, if you require them to have anti-rust properties or want a specific appearance, we usually provide them with an electroplated coating. For example, zinc (whether in transparent color or yellow), nickel, or for aluminum parts, there is also anodized treatment. These surface treatment methods can make them present silver, black or other colors.

As for packaging, these nuts are usually packed in large boxes. Sometimes they are also packed in orderly rolls - those are for automated feeding systems.

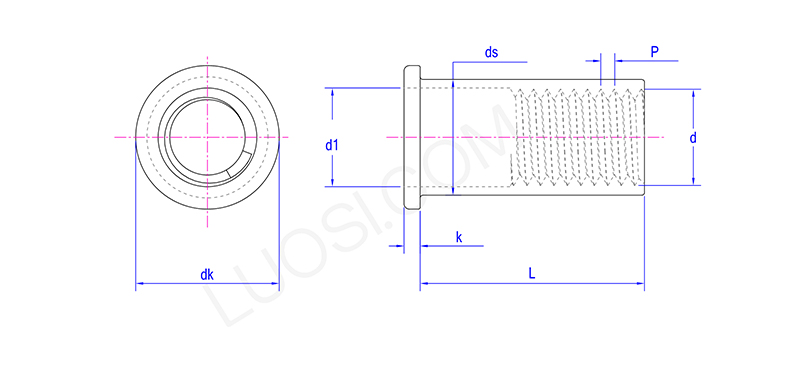

Product Parameters

| Mon | M3 | M4 | M5 | M6 | M8 | M10 | M12 |

| P | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

| ds max | 4.97 | 5.97 | 6.97 | 8.97 | 10.97 | 12.97 | 14.97 |

| ds min | 4.9 | 5.9 | 6.9 | 8.9 | 10.9 | 12.9 | 14.9 |

| d1 max | 4.12 | 4.92 | 5.72 | 7.65 | 9.35 | 11.18 | 13.18 |

| d1 min | 4 | 4.8 | 5.6 | 7.5 | 9.2 | 11 | 13 |

| dk max | 8 | 9 | 10 | 12 | 14 | 16 | 18 |

| k | 0.8 | 0.8 | 1 | 1.5 | 1.5 | 1.8 | 1.8 |

FAQ

Q: What are the typical push-out and torque values for your Aerodynamic Countersunk Head Riveted Nuts?

A:We test the push-out strength (that’s how well it resists being pushed out) and torque strength (how well it keeps threads from stripping) of our Aerodynamic Countersunk Head Riveted Nuts really thoroughly. These values aren’t the same for every nut—they change based on the material, size, and grip range.

Like, a steel one will have way higher push-out and torque values than an aluminum one of the same type. We give detailed mechanical performance charts for each product, too. These numbers matter a lot for engineers—they use them to make sure the fastener can handle the structural demands of the application. That way, the connection stays secure and reliable.