300 Series Stainless Steel Insert Nut

Send Inquiry

The 300 series stainless steel insert nuts are made from chromium-nickel steel (like AISI 304 or 316). The mix has 18-20% chromium and 8-12% nickel to fight rust. AISI 316 types add 2-3% molybdenum, which helps them stand up to acids and chlorides better.

After forging, they go through heat treatment: solution annealing at 1050°C, quick quenching, and aging. This process evens out the carbides in the metal.These nuts are really good at resisting intergranular corrosion and can handle a lot of wear and tear. They even meet ASTM F594 standards, so you know they’re tested and approved.

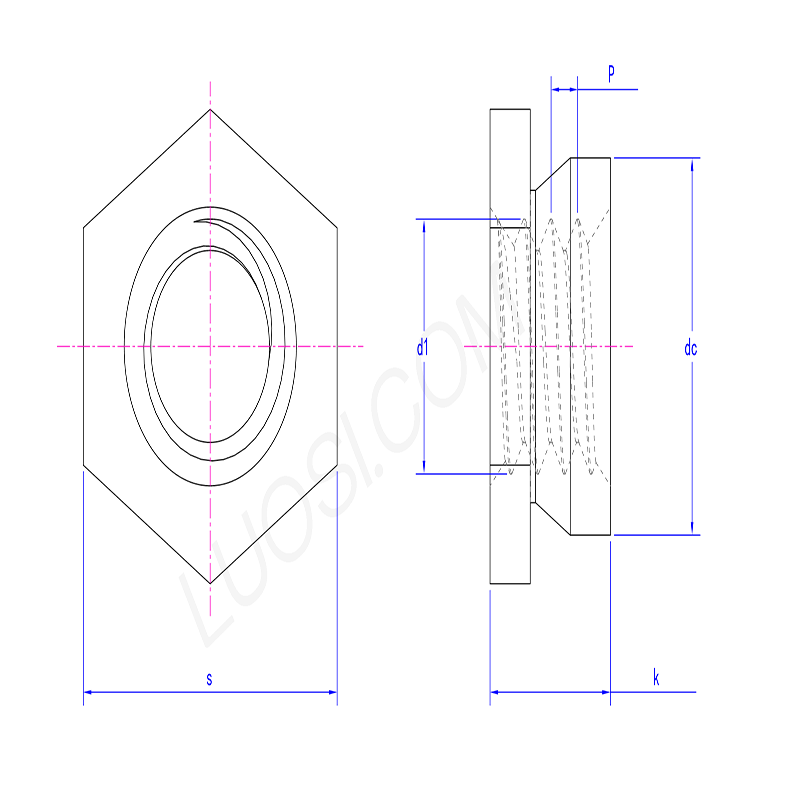

Produter parameters

| Mon | M2.5-1 | M2.5-2 | M3-1 | M3-2 | M4-1 | M4-2 | M5-1 | M5-2 | M6-3 | M6-4 | M6-5 |

| P | 0.45 | 0.45 | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 0.8 | 1 | 1 | 1 |

| dc max | 4.35 | 4.35 | 4.35 | 4.35 | 7.35 | 7.35 | 7.9 | 7.9 | 8.72 | 8.72 | 8.72 |

| k max | 1.53 | 2.3 | 1.53 | 2.3 | 1.53 | 2.3 | 1.53 | 2.3 | 3.05 | 3.84 | 4.63 |

| d1 | M2.5 | M2.5 | M3 | M3 | M4 | M4 | M5 | M5 | M6 | M6 | M6 |

| s | 4.8 | 4.8 | 4.8 | 4.8 | 7.9 | 7.9 | 8.7 | 8.7 | 9.5 | 9.5 | 9.5 |

Maintenance

Taking care of 300 series stainless steel insert nut is pretty easy because they don’t rust much. Just check them once in a while for dirt or salt buildup,you can clean them with mild soap and water. Stay away from cleaners with chlorine, since that can cause little pits in the metal.

If they’re used in high-temperature spots, make sure to check the torque settings every year. Heat cycling can make the fittings loosen over time. When you put them back together, use some anti-seize lubricant to keep them from sticking or getting damaged. These nuts are tough, so with basic maintenance, they’ll last for decades.

What installation methods are recommended?

Our 300 series stainless steel insert nut are made to fit into pre-drilled holes,you can install them with standard tools used in the industry. There’s a hex broach on them, so you can use a hex key to drive them in securely. Since they’re heat-treated, they’re tough enough to handle the torque during installation without cracking or bending out of shape.