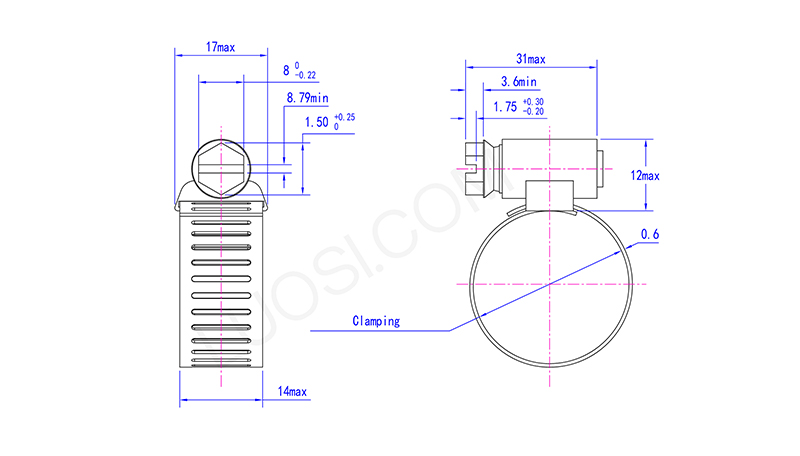

Worm Gear Hose Clamp

Send Inquiry

The worm gear hose clamp is strong, forged build and tough materials hold up way better than standard clamps under heavy use and rough conditions. The worm gear design works consistently and reliably for years, and it doesn’t need much maintenance.

Because it’s so tough, you won’t have to replace it often, and it stops problems like leaks, downtime, or safety issues that cost money. Basically, it’s the most reliable and cost-effective choice for hose connections that matter,you spend a bit more upfront, but it saves you hassle and cash in the long run.

Regular inspection and maintenance:

Taking care of your worm gear hose clamp is important to keep things safe long-term. Check it often for rust, the band being bent out of shape, or stripped threads on the screw. Make sure the band is sitting flat and isn’t digging too deep into the hose.

Put a little grease on the screw threads,especially the kind that stops rust,to make it easier to tighten later and keep it from getting stuck, especially if it’s in a salty or wet area. If the clamp looks worn out, bent, or rusty, swap it out right away so it doesn’t fail on you. Basic stuff, but keeping an eye on it helps avoid problems down the line.

| Mon |

Φ83 |

Φ89 |

Φ95 |

Φ102 |

Φ108 |

Φ114 |

Φ127 |

Φ140 |

Φ152 |

Φ165 |

Φ178 |

|

Clamping range max |

83 | 89 | 95 | 102 | 108 | 114 | 127 | 140 | 152 | 165 | 178 |

|

Clamping range min |

58 | 65 | 71 | 78 | 84 | 90 | 103 | 117 | 130 | 141 | 157 |

Industry Standards:

our hose clamps are built to meet industry standards(especially the ones made from SS316). They comply with AWWA C606 for grooved connections used in water systems and may also meet FDA requirements for indirect food contact. That makes these clamps suitable for drinking water setups or food/beverage applications where following regulations is a must.