Aluminium Alloy Spring Top Standoffs

Send Inquiry

Aluminium alloy spring top standoffs parts typically have a standard mill finish (like 2B or BA). This gives a clean, smooth surface that's easy to wipe down,good enough for most workshop or factory use.

If additional corrosion protection, a smoother surface or a custom appearance is required.You can opt for treatments like electropolishing or passivation. These boost the natural protective layer, making the aluminium alloy self-clinching spring-top standoffs simpler to clean and less prone to pitting corrosion.

Choose the size you need to pay attention to

The aluminium alloy spring top standoffs comes in many standard sizes to suit different needs. You'll mostly see square or rectangular tube shapes,from short pieces to columns several meters tall. Wall thickness varies quite a bit, and this mainly decides how much weight they'll hold.

When picking your size, look at:

1. The profile (like 50x50mm or 80x40mm);

2. Wall thickness;How tall the column is;

3. Hole layout (where the holes are);

4. These specs help you pick the right one for your setup

Advantages of riveted design over welding process

A:Using rivets to build the aluminium alloy spring top standoffs has big pluses. Unlike welding, there's no heat damage to the metal, so the aluminium keeps its full rust resistance. It also means you don't need welding gear or skills on-site,assembly is faster and cleaner. This way, the spring top standoffs stays sturdy while being quicker to install.

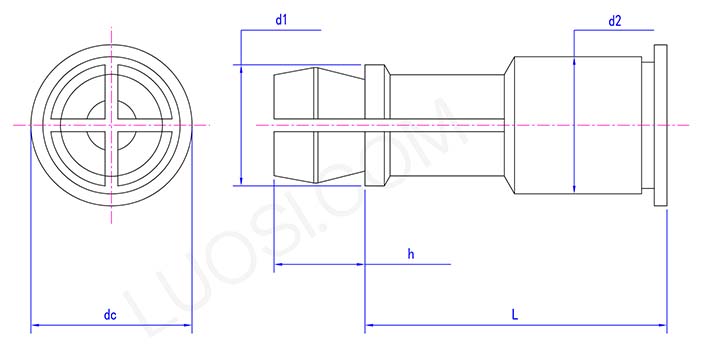

Product parameters

| Mon |

Φ4 |

| d1 max | 4.91 |

| d1 min | 4.65 |

| d2 max | 5.39 |

| dc max | 6.48 |

| d min | 6.22 |

| h max | 3.71 |

| h min | 3.45 |