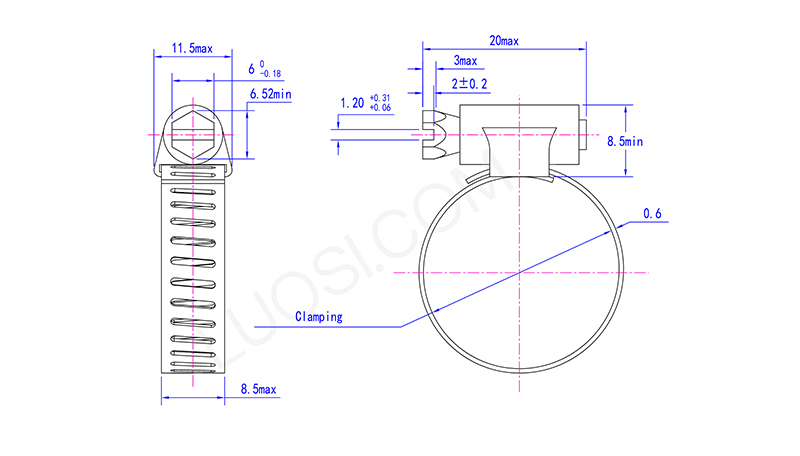

Worm Driven Hose Hoop

Send Inquiry

Most of the time, carbon steel is the go-to for regular use with these worm driven hose hoop, but picking the right material matters a lot when things get tough. If you’re in a marine setting, offshore, working with chemicals, or any place where corrosion is a big deal, AISI 316 stainless steel is the better option. It handles saltwater, chlorides, and lots of chemicals way better than other materials.

This stronger steel keeps the worm-driven hose hoop strong and able to hold tight, even in the roughest environments.

| Mon |

Φ10 |

Φ12 |

Φ16 |

Φ25 |

Φ29 |

|

Clamping range max |

10 | 12 | 16 | 25 | 29 |

|

Clamping range min |

8 | 10 | 12 | 16 | 19 |

Correct Installation:

Putting on a worm driven hose hoop is pretty easy, but you need to do it right. First, wrap the clamp band around where the hose and fitting overlap. Then, slip the worm screw into the housing part. Use the right tool to tighten it, but do it a little at a time,maybe even switch sides as you go to spread the pressure evenly.

The best part about how it works is the worm gear locks itself once it’s tight. That means even if the machine is shaking a lot, the clamp won’t loosen up on its own. This built-in feature makes these clamps really reliable for machines that are always moving or vibrating a ton. Basically, install it properly, and it stays put no matter what.

Size:

Picking the right worm driven hose hoop size is really important. You need to measure the outer diameter (OD) of the hose end you’re clamping. Our clamps are sized to fit specific hose ODs,they’re made for the diameter they’re designed to hold. Check our sizing chart and line up your hose's OD with the suggested clamp size range. This helps you get a good, tight fit and make sure it seals well.