Vibration Resistant Clinching Nut

Send Inquiry

After they're made, vibration resistant clinching nuts often get surface treatments to help them resist rust better and look better. Common ones include zinc plating—clear, yellow, or black chromate— which gives decent protection. There's also zinc-nickel alloy plating that works even better against rust. For stainless steel nuts, passivation is used to make their natural resistance as good as possible. Which treatment you choose depends on where the nut will be used and how it needs to look. The way vibration resistant clinching nuts are installed naturally keeps this coating intact right where the joint is, which is important.

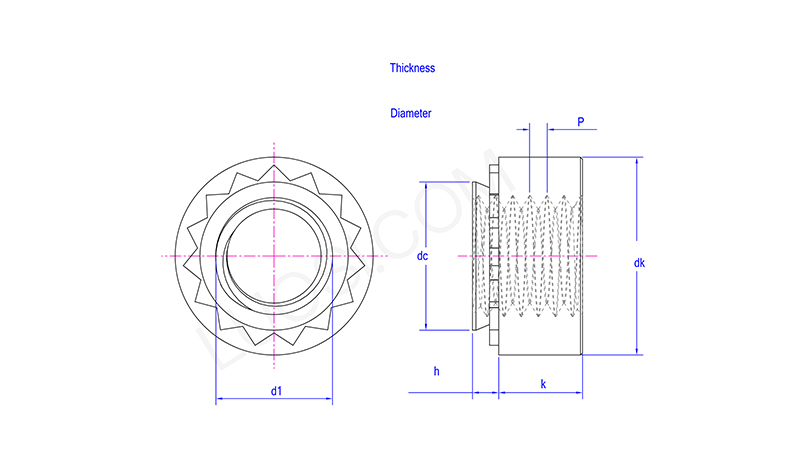

Product parameter details:

Vibration resistant clinching nut sizes are standardized pretty carefully. The main specs include thread size—like metric from M3 to M12, or imperial from #4-40 to 1/2"-13 UNC/UNF. There's also the head style—hex, square, round—plus head diameter, shank diameter and length, and the size of the clinch parts (like knurl outer diameter and height), along with overall height.

One important thing is that the pilot diameter has to match the thickness and properties of the material it's going into. Manufacturers give detailed sheets that list the minimum and maximum sheet thickness, hole size (if it's pre-pierced), and the installation force needed for each type of vibration resistant clinching nut.

| Mon | M2-0 | M2-1 | M2-2 | M2.5-0 | M2.5-1 | M2.5-2 | M3-0 | M3-1 | M3-2 | M3.5-0 | M3.5-1 |

| P | 0.4 | 0.4 | 0.4 | 0.45 | 0.45 | 0.45 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 |

| dc max | 4.2 | 4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

4.73 | 4.73 |

| dk min | 6.05 |

6.05 |

6.05 |

6.05 |

6.05 |

6.05 |

6.05 |

6.05 |

6.05 |

6.85 | 6.85 |

| dk max | 6.55 | 6.55 |

6.55 |

6.55 |

6.55 |

6.55 |

6.55 |

6.55 |

6.55 |

7.35 | 7.35 |

| k min | 1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

| k max | 1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

| h coder | 0 | 1 | 2 | 0 | 1 | 2 | 0 | 1 | 2 | 0 | 1 |

| h max | 0.77 | 0.97 | 1.38 | 0.77 | 0.97 | 1.38 | 0.77 | 0.97 | 1.38 | 0.77 | 0.97 |

|

Thickness of mounting plate min |

0.8 | 1 | 1.4 | 0.8 | 1 | 1.4 | 0.8 | 1 | 1.4 | 0.8 | 1 |

|

Diameter of mounting holes min |

4.22 | 4.22 |

4.22 |

4.22 |

4.22 |

4.22 |

4.22 |

4.22 |

4.22 |

4.75 | 4.75 |

|

Diameter of mounting holes max |

4.3 |

4.3 |

4.3 |

4.3 |

4.3 |

4.3 |

4.3 |

4.3 |

4.3 |

4.83 | 4.83 |

| d1 | M2 | M2 | M2 | M2.5 | M2.5 | M2.5 | M3 | M3 | M3 | M3.5 | M3.5 |

How strong is the connection provided by a vibration resistant clinching nut?

A nut that's put in right makes a really strong connection. You can tell how strong it is by two things: how hard it is to push it through the sheet (push-out force) and how well it resists spinning when there's pressure on it (torque-out resistance).

How strong it is depends on the nut's size, what it's made of, how thick the sheet is and what the sheet's made of, and how well it was installed. A lot of the time, it's just as strong as a weld nut.