Metric Nylon Lock Nut

Send Inquiry

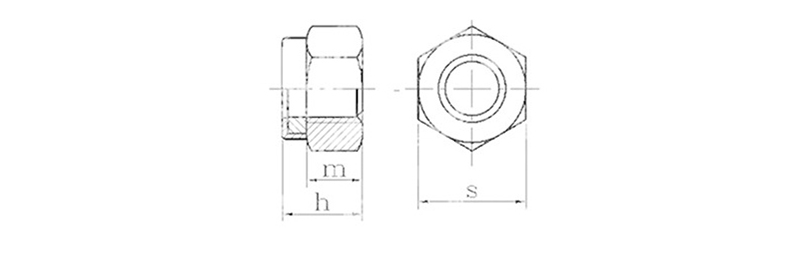

This Metric Nylon Lock Nut has two main parts: the outer metal body and the inner nylon insert. The metal part is usually made of carbon steel for regular use. It’s affordable and works for most indoor jobs, like small machinery or furniture assembly. It also has basic surface treatment to prevent mild rust.

For damp or outdoor use, stainless steel is a better choice. It holds up well against water and humidity, so it won’t rust easily. The nylon insert is typically common nylon material—tough enough to grip the bolt and stop it from loosening. All materials meet basic industry standards. It uses these standard materials, so you can pick the metal type based on where you’ll use it.

Product surface treatment

The surface treatment here is only for theMetric Nylon Lock Nut’s metal part—since the nylon insert doesn’t need it. The most common one is zinc plating. It’s simple and cheap, good for regular indoor use. It forms a thin layer on the metal to stop mild rust, which works for things like furniture or small indoor machinery.

For outdoor or damp places, we use hot-dip galvanizing. It’s a thicker coat, so it holds up better against rain or humidity. Some nuts for industrial use get black oxide treatment; it adds a bit more protection against wear, nothing fancy. These treatments don’t change the nut’s shape or how it works. It gets these basic treatments based on where it’ll be used, just to keep the metal part in good condition.

Q&A Session

Q: What temperature range can Metric Nylon Lock Nut handle? Will the nylon part melt in high-heat environments?

A:The common nylon insert works well between -20°C and 80°C. If the environment is hotter than that—like near engines or heating parts—the nylon might soften or even melt, losing the locking function. For high-heat jobs, we have options with heat-resistant nylon that can handle up to 120°C. Just tell us the temperature of the place you’ll use it, and we can recommend the right type. Normal indoor or outdoor use with no extreme heat is totally fine for the standard version.

| D P | H | M | S | ||

| M3 | 0.5 | 3.8 | 2.4 | 5.42 | |

| M4 | 0.7 | 4.8 | 2.9 | 6.93 | |

| M5 | 0.8 | 4.9 | 3.2 | 7.89 | |

| M6 | 1 | 5.9 | 4 | 9.83 | |

| M8 | 1.25 | 7.8 | 5.5 | 12.92 | |

| M10 | 1.5 | 9.8 | 6.5 | 16.92 | |

| M12 | 1.75 | 11.6 | 8 | 18.92 | |

| M14 | 2 | 13.8 | 9.5 | 21.93 | |

| M16 | 2 | 15.8 | 10.5 | 23.96 | |

| M18 | 2.5 | 17.9 | 13 | 26.84 | |

| M20 | 2.5 | 19.3 | 14 | 29.54 | |

| M22 | 2.5 | 21.3 | 15 | 31.53 | |

| M24 | 3 | 23.4 | 16 | 35.85 | |

| M27 | 3 | 26.3 | 17 | 40.45 | |

| M30 | 3.5 | 29.3 | 19 | 45.62 | |

| M33 | 3.5 | 32.5 | 22 | 49.51 | |

| M36 | 4 | 35.1 | 25 | 54.41 | |

| M39 | 4 | 38.5 | 38 | 59.54 | |

| M42 | 4.5 | 41.5 | 29 | 64.21 | |

| M45 | 4.5 | 44.5 | 32 | 69.41 | |

| M48 | 5 | 47.6 | 36 | 74.45 | |