Vibration Defying Two Fold Self Locking Washers

Send Inquiry

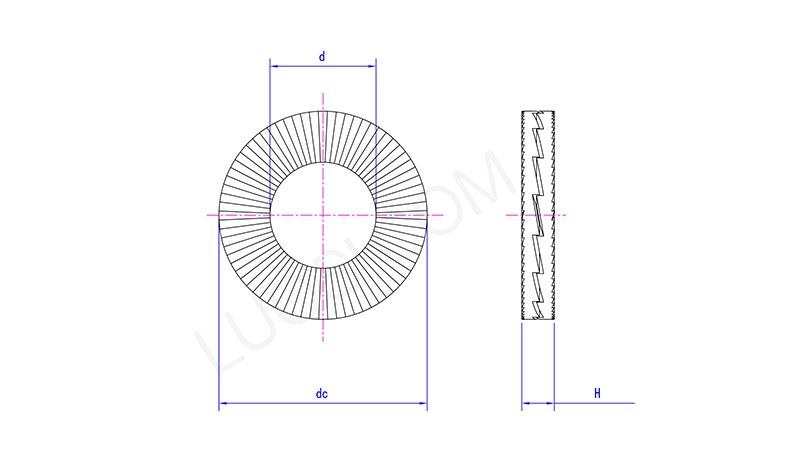

Vibration defying two fold self locking washers have key measurements that matter: the size that matches the bolt diameter, the inner diameter, outer diameter, and total thickness. The thickness is important because it affects how much the washer can spring back and the locking force it creates. Manufacturers give detailed specs for each type and size of these washers. That way, engineers can pick the right one for the bolt size and what they need it to do.

Comply With International Standards:

Good manufacturers make vibration defying two fold self locking washers that meet strict international standards, like DIN 25201, NASM 35338, or specific specs from original equipment makers—think car or airplane companies. These standards cover things like size, material properties, hardness, how well they need to perform (like the minimum force to keep them from turning), and how to test them. This makes sure that certified Vibration-Defying Two-fold self-locking washers work reliably and can be swapped out for each other in important assemblies.

What is the maximum continuous operating temperature range for your standard vibration defying two fold self locking washers?

Our regular carbon steel vibration defying two fold self locking washers with zinc plating work fine up to around 120°C (250°F). If you need them for higher temps—up to about 400°C (750°F)—we suggest our A2 (304) or A4 (316) stainless steel ones. They keep locking things properly without getting worse even at those higher temperatures.

| Mon |

Φ12 |

Φ14 |

Φ16 |

Φ18 |

Φ20 |

Φ22 |

Φ24 |

Φ27 |

Φ30 |

Φ33 |

Φ36 |

| d max | 13.2 | 15.4 | 17.2 | 19.7 | 21.6 | 23.6 | 25.5 | 28.6 | 31.6 | 34.6 | 37.6 |

| d min | 12.8 | 15 | 16.8 | 19.3 | 21.2 | 23.2 | 25.1 | 28.2 | 31.2 | 34.2 | 37.2 |

| dc max | 25.7 | 31 | 31 | 34.8 | 39.3 | 42.3 | 48.8 | 48.8 | 58.8 | 58.8 | 63.3 |

| dc min | 25.1 | 30.4 | 30.4 | 34.2 | 38.7 | 41.7 | 48.2 | 48.2 | 58.2 | 58.2 | 62.7 |

| H max | 3.65 | 3.65 | 3.65 | 3.65 | 3.65 | 4.85 | 4.85 | 6.05 | 6.6 | 6.6 | 6.5 |

| H min | 3.15 | 3.15 | 3.15 | 3.15 | 3.15 | 4.35 | 4.35 | 5.55 | 6.1 | 6.1 | 6.1 |