Variable Tooth Type Anti Loose Nut

Send Inquiry

The variable tooth type anti loose nut has a tooth design that changes shape slightly when it encounters some pressure, thus creating additional friction. It prevents loosening due to vibration or movement. It is made of steel or stainless steel. It is used on machinery, vehicles or equipment.

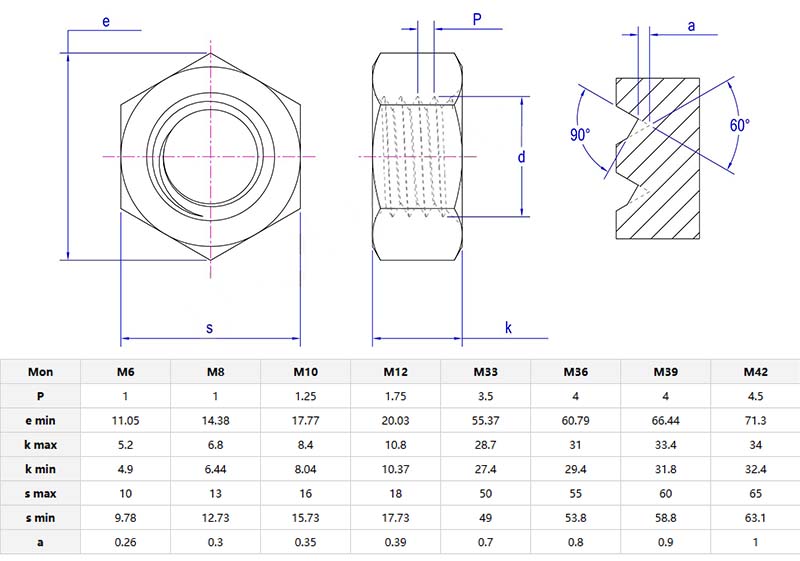

Product details and parameters

Variable tooth type anti loose nut is different from standard nuts, it does not need lock washers or adhesives - just tighten with a wrench and the variable teeth will grab the bolt threads. Easy to operate, reusable, adapt to shaking or high pressure environments.

Variable tooth type anti loose nut can withstand severe vibration better than regular nuts and works well in hot or oily conditions where nylon inserts fail. The teeth flex when tightened, locking onto the bolt threads like a built-in brake. Variable tooth type anti-loose nut is slightly more expensive than regular nuts, but saves time and hassle by reducing maintenance checks. Great for engines, conveyors or outdoor gear.

Variable tooth type anti loose nut is used in places where vibrations can damage standard fasteners. For example: securing truck wheel hubs, tightening industrial fan blades or assembling fitness equipment with moving parts. It is also suitable for outdoor structures such as solar panel frames or bridges, where wind and weather can loosen bolts over time.

Our market distribution

|

Market |

Total Revenue (%) |

|

North America |

15 |

|

South America |

22 |

|

Eastern Europe |

16 |

|

Southeast Asia |

5 |

|

Mid East |

7 |

|

Eastern Asia |

13 |

|

Western Europe |

12 |

|

Central America |

5 |

|

South Asia |

10 |

|

Domestic Market |

5 |

Maintenance Tips

The variable tooth type anti loose nut is low-maintenance but check the teeth for wear after removal. If they’re flattened or damaged, replace the nut. Avoid over-tightening, which can strip threads. For outdoor use, pick stainless steel to resist rust. Reuse is possible if the teeth still grip, but for critical jobs (like heavy machinery), swap old nuts for new ones. Simple care, long-term hold.