Type C Worm Driven Hose Hoop

Send Inquiry

To fight rust and help type C worm driven hose hoop last longer, the parts get surface treatments. A common one is hot-dip galvanizing,basically dipping the worm-driven hose hoop in molten zinc to put on a thick rust-fighting layer. Carbon steel clamps might get a yellow chromate coating instead. Stainless steel C type worm driven hose hoops rely on their own natural protective layer.

These treatments mean the C worm driven hose hoop can handle wet, salty, or outdoor spots like boat decks, chemical plants, or fire scenes. They stop the clamp parts from corroding, which could make the worm-driven hose hoop loosen up over time. Basically, the coatings help them keep working where rust would normally cause trouble.

Size:

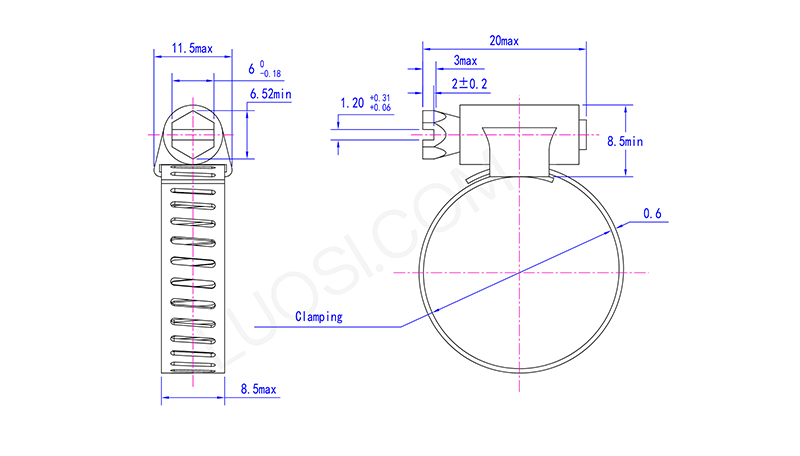

Type C worm driven hose hoop come in standard sizes made for specific hose diameters. You'll typically find them from around 1.5 inches (38mm) up to 6 inches (152mm), with bigger ones available for heavy work. Each size comes with its own band width (usually 1 inch / 25mm) and thickness (like 0.125 inches / 3mm) so it's strong enough.

You'll want to check the band length, the worm screw's size and thread spacing, and what tool tightens it,a hex key or screwdriver size. Picking the right size C worm-driven hose hoop is key to getting a good seal. Bottom line: match the clamp to your hose's outside measurement for a tight fit that won't leak.

| Mon |

Φ10 |

Φ12 |

Φ16 |

Φ25 |

Φ29 |

|

Clamping range max |

10 | 12 | 16 | 25 | 29 |

|

Clamping range min |

8 | 10 | 12 | 16 | 19 |

Installation Tools:

You can install our C worm driven hose hoop with basic tools,probably ones you already have on hand. Just use a standard flat-head screwdriver or the right socket wrench to tighten the worm screw. This keeps things simple: your crew can fit or adjust them in the field without buying expensive gear or hunting down specialized tools.