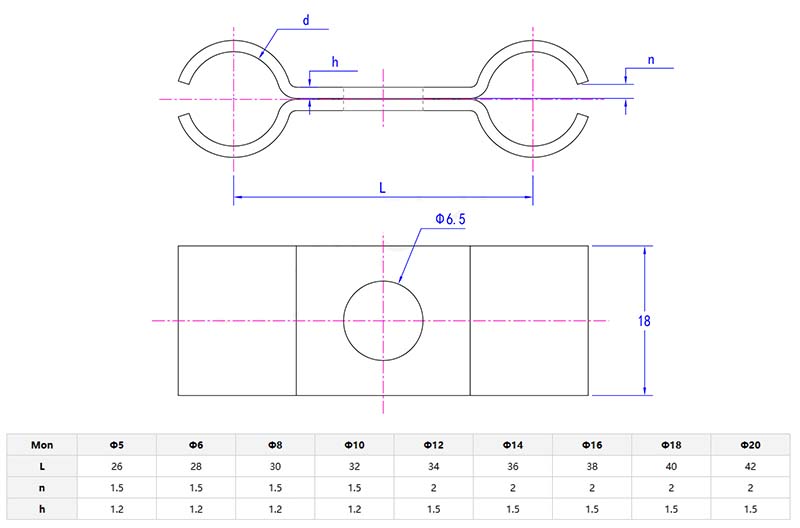

M Type Clamp

Send Inquiry

To make M Type Clamp last longer and work better, they get special surface treatments. Stuff like:

Anodizing for aluminum ones: Makes 'em rust less and toughens up the surface.

Hot-dip galvanizing for steel: They dunk it in molten zinc – gives a thick coat that protects it.

Powder coating: A tough finish that stops rust and comes in colors.

Stainless steel clamps often get treated too. It helps them fight rust even better, so they hold up fine in wet or nasty spots.

Product detail

M Type Clamp come in lots of different sizes to fit different tube, pipe, or structural diameters. Standard sizes usually go from small tubing (like 10mm) up to large pipes (300mm or bigger). They have two matching halves that connect with strong steel bolts (like grade 8.8 or stronger) and nuts. This lets you adjust them precisely and control how tight they are by how much you torque the bolts during installation—basically, how hard you tighten them.

FAQ

Q: What corrosion protection is offered on your Clamp for harsh environments like marine applications or chemical plants?

A: Our regular M Type Clamp come with zinc plating. That helps them fight rust in everyday use. If you're dealing with tougher spots—like near the ocean or around chemicals—we've got you covered. You can get:

Versions made from 316 stainless steel

Or ones with HDG coating (hot-dip galvanizing)

These give heavy-duty protection against saltwater, chemicals, or dampness. That means the clamps keep holding tight and last longer, even when things get rough.