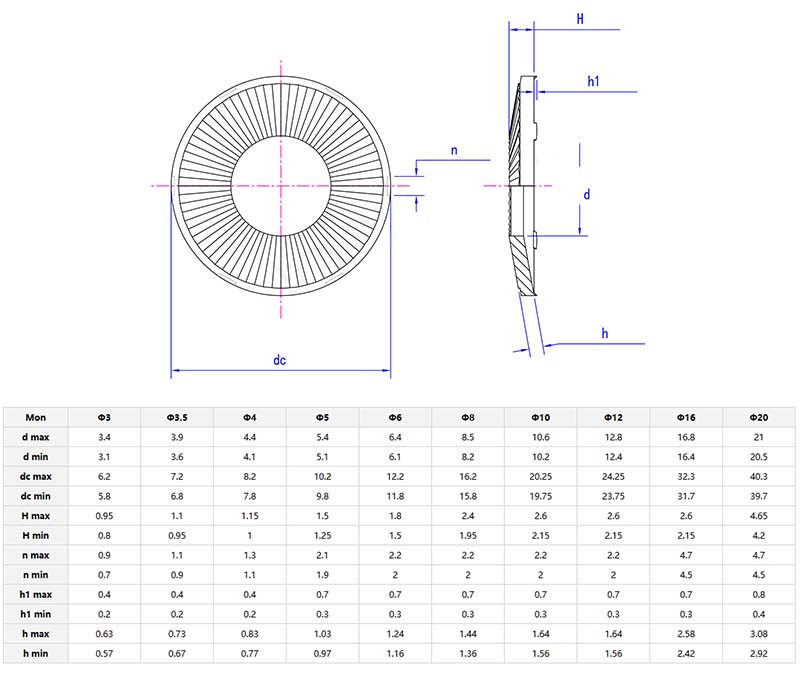

Twin Layer Self Locking Washer

Send Inquiry

Tests show the twin layer self locking washer works well. In vibration tests following DIN 25201-4, it didn’t loosen even after over 10,000 cycles at 30 Hz. Salt spray tests (ASTM B117) showed it resists corrosion for more than 500 hours. Tensile strength tests also meet ISO 898-1 standards.Double-layer self-locking washers are more appropriate and more secure in important situations, like on offshore rigs or in car drivetrains.

Features

The dual disc self locking washer cuts down waste by replacing single-use locking parts, which matches environmental goals. Since you can reuse it, you don’t have to swap it out as often, and less downtime means lower operating costs. The way it’s made uses energy-efficient processes and recyclable materials, which also helps reduce its carbon footprint.

By preventing major breakdowns, the twin layer self locking washer makes equipment last longer. It’s a eco-friendly and cost-saving choice compared to old-school fastening methods.

Cost

Q: How do these double layer self locking washer compare on cost to things like nylon lock nuts or glue-based thread locker?

A: Yeah, the twin layer self locking washers might cost a bit more upfront than basic washers or those cheap nylon nuts. But here’s the thing,you’ll save money over time. With traditional options, you’re constantly buying more adhesive, replacing worn-out fasteners, or dealing with downtime when stuff comes loose and breaks. Nylon lock nuts fall apart in really hot temps or when they’re exposed to the sun a lot. The all-metal washers keep working fine in tough conditions where nylon would fail. And unlike those thread-locking glues, chemicals won’t eat through them either. Plus, you can reuse these washers over and over. That means less waste and less money tied up in storing extra parts. For industries that need things to stay secure and want to cut long-term costs, these washers end up being a better deal than the old-school locking methods.