Time Saving Clinching Nut

Send Inquiry

To get a time saving clinching nut installed right, you need a compatible press—could be hydraulic, pneumatic, or servo-electric—with good control over the tonnage, plus properly made tools (a punch and die set). The punch pushes directly on the nut, driving it into the sheet metal that's set over a supporting die cavity. A well-designed die lets the material flow in a controlled way into the nut's clinching parts. Keeping the force steady and everything aligned is really important. If you don't use enough force, the clinch will be weak. Use too much, and you might damage the nut or the sheet. And you don't need to pre-thread anything first.

Applicable Scenarios:

Time saving clinching nuts are used a lot in industries that need to put sheet metal together efficiently. You’ll find them in cars—for body panels, brackets, chassis parts. They’re also in electronics, like enclosures, racks, and heat sinks. HVAC systems use them too, in ducting and units. Appliances, with their frames and housings, telecommunications cabinets, furniture, and lighting—they all use Time-Saving Clinching nuts.

Any job that needs a strong, dependable threaded stud sticking out of sheet metal (and sitting flush) works well with a time saving clinching nut. It replaces those bulky weld nuts or loose fasteners, making both design and manufacturing simpler.

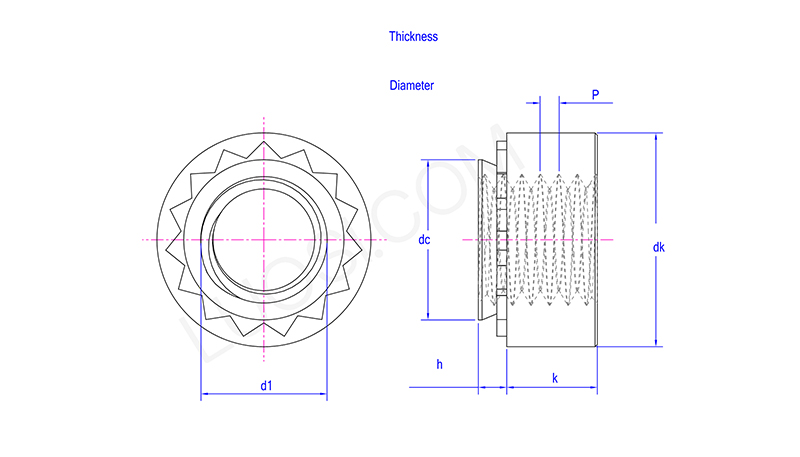

| Mon | 256-0 | 256-1 | 256-2 | 348-0 | 348-1 | 348-2 | 440-0 | 440-1 | 440-2 | 440-3 | 632-0 |

| P | 56 | 56 | 56 | 48 | 48 | 48 | 40 | 40 | 40 | 40 | 32 |

| d1 | #2 |

#2 |

#2 |

#3 |

#3 |

#3 |

#4 |

#4 |

#4 |

#4 |

#6 |

| dc max | 0.165 | 0.165 | 0.165 | 0.165 |

0.165 |

0.165 |

0.165 |

0.165 |

0.165 |

0.165 |

0.187 |

|

Diameter of mounting holes min |

0.166 | 0.166 |

0.166 |

0.166 |

0.166 |

0.166 |

0.166 |

0.166 |

0.166 |

0.166 |

0.1875 |

|

Diameter of mounting holes max |

0.169 |

0.169 |

0.169 |

0.169 |

0.169 |

0.169 |

0.169 |

0.169 |

0.169 |

0.169 |

0.1905 |

| dk min | 0.24 | 0.24 | 0.24 |

0.24 |

0.24 |

0.24 |

0.24 |

0.24 |

0.24 |

0.24 |

0.27 |

| dk max | 0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

0.29 |

| h max | 0.03 | 0.038 | 0.054 | 0.03 | 0.038 | 0.054 | 0.03 | 0.038 | 0.054 | 0.087 | 0.03 |

| h coder | 0 | 1 | 2 | 0 | 1 | 2 | 0 | 1 | 2 | 3 | 0 |

| k max | 0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

| k min | 0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

0.06 |

|

Thickness of mounting plate min |

0.03 | 0.04 | 0.056 | 0.03 | 0.04 | 0.056 | 0.03 | 0.04 | 0.056 | 0.091 | 0.03 |

Anti-rust treatment:

This nut often have surface treatments to help them resist rust and look better. Common ones include zinc plating—clear, yellow, or black—zinc-nickel plating, Geomet® (a non-electrolytic inorganic coating), and passivation for stainless steel. The coating needs to hold up against the high pressure of the clinching process without chipping off.