T head bolts with large head

Send Inquiry

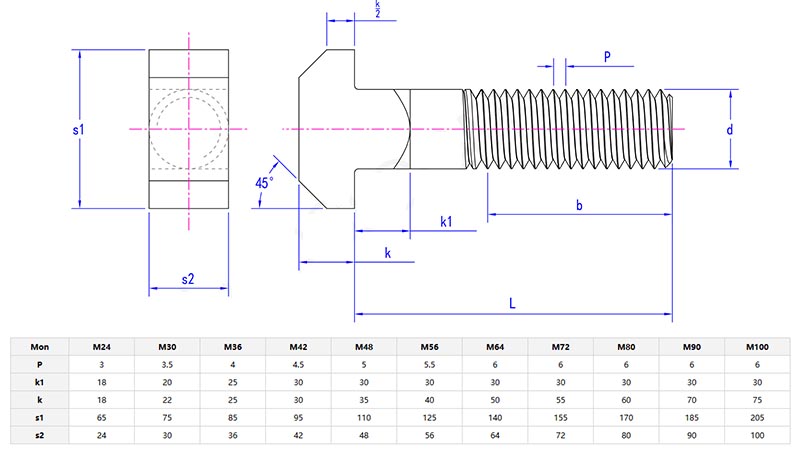

T head bolts with large head have a big T-shaped head. They are easy to position, have a large force-bearing area, can withstand greater pressure and have a more secure connection. The sizes available are M24, M30, M36, M42, M48, M56, M64, M72, M80, M90 and M100.

Product details and parameters

They are used to replace the bottom plate of the trailer. Bolts cannot pass through rotten wood; they can distribute the pressure to soft areas. Slide the bolt into the slot and rotate it downward with the crank. This way, the plywood can be firmly fixed even on bumpy roads.

T head bolts with large head are used for installing metal roof trim strips. Bolts can firmly grasp the joints of thin metals. Slide into the trim track, which can disperse the pressure and prevent the metal plate from tearing. Tighten from the bottom to prevent the fragile profiles from being crushed during the construction of a windy roof.

T-head bolts with large heads can be used to assemble playground climbing boards. Fix the composite panels to the frame with bolts. They are suitable for extruding the tracks. When tightened, the bolt will not damage the brittle plastic around the bolt hole. Through safety checks, there are no sharp edges protruding, and it can prevent children from constantly shaking and causing loosening.

Product parameters

Application scenario

T head bolts with large head are applied in the logistics and warehousing industry. They will be used when building large shelves. Warehouse shelves have to bear the weight of a large amount of goods. Frequent access to and retrieval of goods cannot cause them to shake or collapse. When setting up the shelves, make T-shaped grooves on the uprights and beams of the shelves, and use them to connect the beams and uprights.