Streamlined Clinching nut

Send Inquiry

A big plus of Streamlined Clinching nuts is how well they hold up mechanically. The cold-formed lock they create is strong against being pushed out, pulled out, or twisted off—often stronger than the sheet metal around them. This clinched connection really resists coming loose from vibrations, which is a common problem with regular nuts and bolts.

Streamlined Clinching nuts make sure the connection stays tight and doesn’t rattle, which is important in places that move, like vehicles and machines. That helps the product last longer and work more reliably.

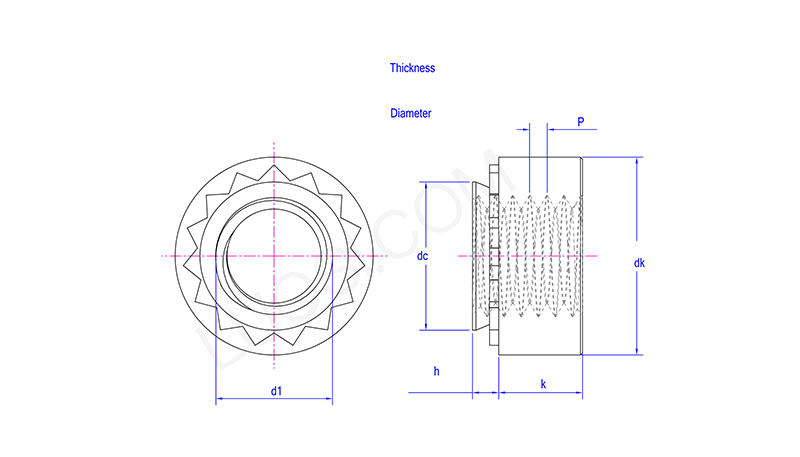

| Mon | M2-2 | M3-1 | M3-2 | M3.5-1 | M3.5-2 | M4-1 | M4-2 | M5-1 | M5-2 | M6-1 | M6-2 |

| P | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.7 | 0.7 | 0.8 | 0.8 | 1 | 1 |

| dc max | 4.22 | 4.73 | 4.73 | 5.38 | 5.38 | 5.97 | 5.97 | 7.47 | 7.47 | 8.72 | 8.72 |

| dk min | 6.05 | 6.05 | 6.05 | 6.85 | 6.85 | 7.65 | 7.65 | 9.25 | 9.25 | 11.3 | 11.3 |

| dk max | 6.55 | 6.55 | 6.55 | 7.35 | 7.35 | 8.15 | 8.15 | 9.75 | 9.75 | 11.8 | 11.8 |

| k min | 1.25 | 1.75 | 1.75 | 1.75 | 1.75 | 2.75 | 2.75 | 3.55 | 3.55 | 3.83 | 3.83 |

| k max | 1.75 | 2.25 | 2.25 | 2.25 | 2.25 | 3.25 | 3.25 | 4.05 | 4.05 | 4.33 | 4.33 |

| h coder | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 |

| h max | 1.38 | 0.98 | 1.38 | 0.98 | 1.38 | 0.98 | 1.38 | 0.98 | 1.38 | 1.38 | 2.21 |

|

Thickness of mounting plate min |

1.4 | 1 | 1.4 | 1 | 1.4 | 1 | 1.4 | 1 | 1.4 | 1.4 | 2.3 |

|

Diameter of mounting holes min |

4.25 | 4.75 | 4.75 | 5.4 | 5.4 | 6 | 6 | 7.5 | 7.5 | 8.75 | 8.75 |

|

Diameter of mounting holes max |

4.33 | 4.83 | 4.83 | 5.48 | 5.48 | 6.08 | 6.08 | 7.58 | 7.58 | 8.83 | 8.83 |

| d1 | M2 | M3 | M3 | M3.5 | M3.5 | M4 | M4 | M5 | M5 | M6 | M6 |

Product Advantages:

Streamlined Clinching nuts have some good points when it comes to design. They give you a threaded stud that sits flush or low on one side of the sheet metal, which is handy when there's not much space behind the panel. That means you don't need big backing plates or extra room for wrenches or nuts on the hidden side.

Designers get more flexibility—assemblies are simpler, and you use fewer parts. With Streamlined Clinching nuts, you only need access to the thread from one side. That makes putting things together and taking them apart easier than with weld nuts, especially in tight spots.

Suitable sheet metal thickness:

The thickness of the boards that can be used with these nuts generally ranges from half a millimeter to 6 millimeters (about as thin as a fingernail to as thick as two or three bank cards stacked together). The key is to choose the right nut—the thicker the board, the thicker the nut! If you force a nut designed for thicker boards onto thinner ones, you could tear the board or create a hole!