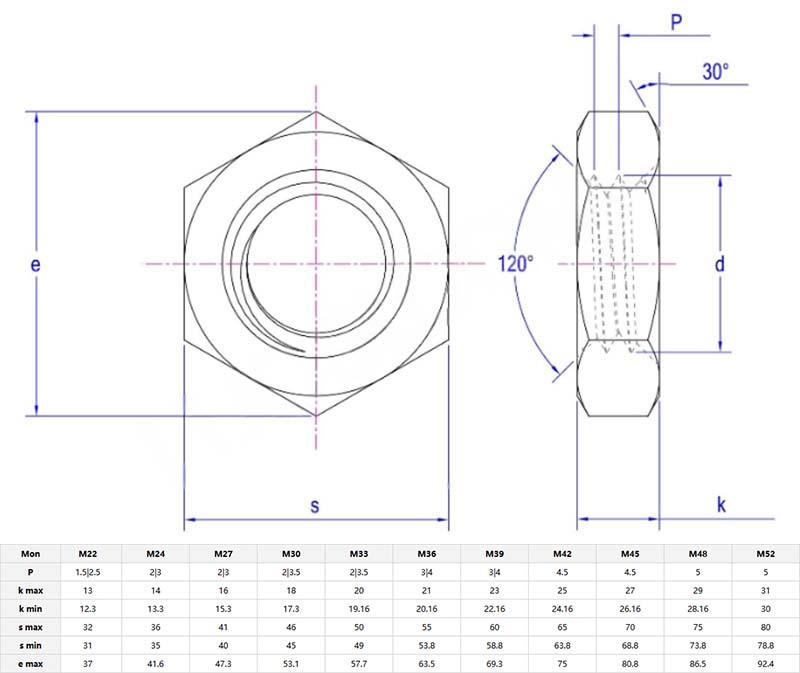

Semi Finished Hexagon Thin Nut

Send Inquiry

Semi finished hexagon thin nuts need to be processed by tapping, grinding and coating. If conditions permit, you can do it yourself, or you can tell us your needs and we will carry out subsequent processing to meet your requirements.It is thinner than ordinary hexagonal nuts, making it convenient for workers to install and saving time.

Features and parameters

DIY enthusiasts like to use the semi finished hexagon thin nut for customizing bicycles or shelves. Unprocessed steel can be sprayed or powder-coated to achieve a polished effect. The pitch (US/metric) should match the bolt. If not, it will waste time and materials.

Why choose semi finished hexagon nut? Because they are cheaper than pre-coated nuts and you can control their durability. It is applicable to mechanical or automotive maintenance. When used outdoors, it can undergo hot-dip galvanizing treatment. When used indoors, it should remain in its original state.

This hexagon thin nut can be used for prototyping, DIY repair or metal art, etc. The thin appearance reduces the weight of the nut, and the original steel is easy to weld or spray. Before spraying, the burrs on the edges should be removed to avoid rough spots.

Advantage

You can add threads, grind the surface or adjust the size of the semi finished hexagon thin nut according to your needs. They are often used in industries such as manufacturing, maintenance and even DIY. It is made of durable materials and can withstand daily wear and tear. It can fix objects together without taking up too much space. You can customize nuts according to your own preferences.