Self Clinching Blind Threaded Standoff

Send Inquiry

Self clinching blind threaded standoff is actually usually made from stainless steel, types like A2 (304) or A4 (316). Picking stainless steel means it's really good at not rusting or corroding. That's super important if you're using it somewhere tough,like near the ocean, around chemicals, or just outside in the weather. Stainless is also just strong and tough in general.

Why does the material matter? Well, because when you rivet it, the steel bends just right without cracking. Plus, the threads it holds stay smooth, even if you're screwing bolts in and out a lot. That's basically what makes it last a long time without problems.

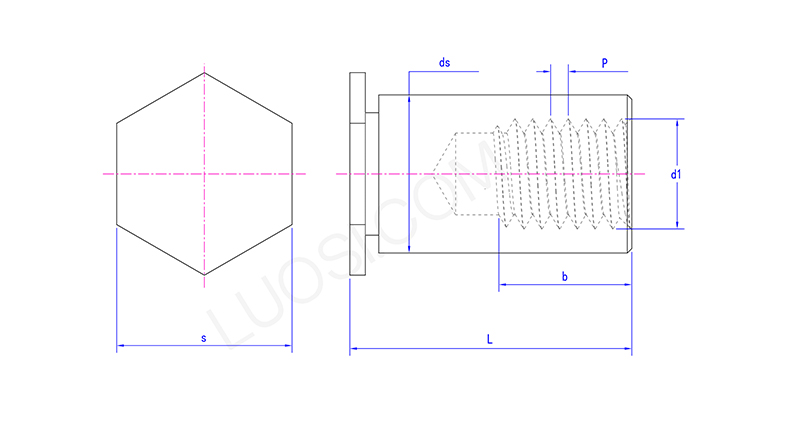

| Mon | M3 | 3.5M3 | M3.5 | M4 | M5 |

| P | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 |

| d1 | M3 | 3.5M3 | M3.5 | M4 | M5 |

| ds max | 4.2 | 5.39 | 5.39 | 7.12 | 7.12 |

| ds min | 4.07 | 5.26 | 5.26 | 6.99 | 6.99 |

| s | 4.8 | 6.4 | 6.4 | 7.9 | 7.9 |

Application Scenario:

The self clinching blind threaded standoff is widely used in tough industries. You’ll see it holding panels, covers, and parts in stainless steel enclosures, cabinets, electrical boxes, and machine housings. It’s important in transportation,like rail,marine, and car sub-assemblies,food processing equipment (where surfaces need to be hygienic), architectural metalwork, and any place thin sheet metal needs a strong, flush-mounted threaded anchor that resists rust.

This riveted nut is great when you need to take things apart for maintenance without damaging the threads.

How to install, and what tools are required?

To install the self clinching blind threaded standoff, you’ll need a riveting tool. First, drill a hole in the material, then stick the nut’s shank into the hole. The tool pulls a mandrel through the nut, which makes the shank bulge out on the backside of the material. That creates a permanent, vibration-proof threaded fastener. Just use a standard pneumatic or hydraulic rivet nut tool that matches the nut’s size,pretty straightforward.