Secure Clinching Nut

Send Inquiry

The main pluses of Secure Clinching nuts are that they cut down a lot on assembly time and cost because you don't need welding, tapping, or through-hole hardware. They hold up better against being pulled out or twisted off than many welded studs. Putting them in is clean work—no heat, sparks, fumes, or things like weld wire or gas. That makes things safer and helps meet environmental rules. Unlike welding, using Secure Clinching nuts doesn't mess up the base metal's coating or its internal structure. This keeps the joint area resistant to rust and maintains the material's strength.

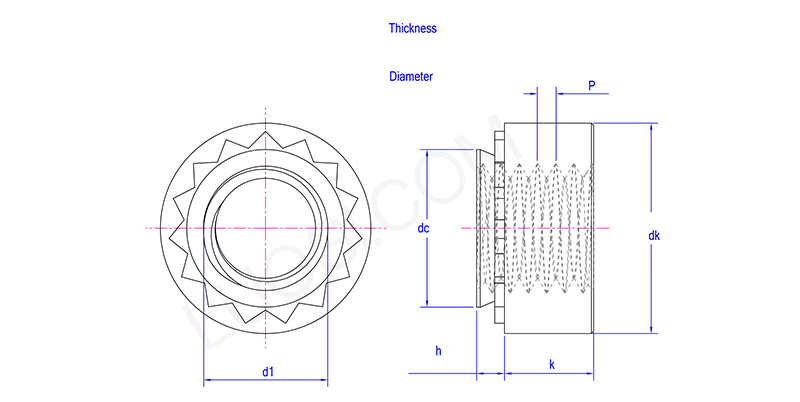

| Mon | 256-1 | 256-2 | 440-1 | 440-2 | 632-1 | 632-2 | 832-1 | 832-2 | 024-1 | 024-2 | 032-1 |

| P | 56 | 56 | 40 | 40 | 32 | 32 | 32 | 32 | 24 | 24 | 32 |

| d1 | #2 |

#2 |

#4 |

#4 |

#6 |

#6 |

#8 |

#8 |

#10 |

#10 |

#10 |

| dc max | 0.165 | 0.165 | 0.343 | 0.343 | 0.212 | 0.212 | 0.233 | 0.233 | 0.295 | 0.295 | 0.295 |

|

Diameter of mounting holes min |

0.166 | 0.166 | 0.344 | 0.344 | 0.213 | 0.213 | 0.234 | 0.234 | 0.296 | 0.296 | 0.296 |

|

Diameter of mounting holes max |

0.169 | 0.169 | 0.347 | 0.347 | 0.216 | 0.216 | 0.237 | 0.237 | 0.299 | 0.299 | 0.299 |

| dk max | 0.26 | 0.26 | 0.45 | 0.45 | 0.29 | 0.29 | 0.32 | 0.32 | 0.38 | 0.38 | 0.38 |

| dk min | 0.24 | 0.24 | 0.43 | 0.43 | 0.27 | 0.27 | 0.3 | 0.3 | 0.36 | 0.36 | 0.36 |

| h max | 0.038 | 0.054 | 0.054 | 0.087 | 0.038 | 0.054 | 0.038 | 0.054 | 0.038 | 0.54 | 0.038 |

| h coder | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 |

| k max | 0.08 | 0.08 | 0.18 | 0.18 | 0.1 | 0.1 | 0.14 | 0.14 | 0.17 | 0.17 | 0.17 |

|

k min |

0.06 | 0.06 | 0.16 | 0.16 | 0.08 | 0.08 | 0.12 | 0.12 | 0.15 | 0.15 | 0.15 |

|

Thickness of mounting plate min |

0.04 | 0.056 | 0.056 | 0.091 | 0.04 | 0.056 | 0.04 | 0.056 | 0.04 | 0.056 | 0.056 |

Product Details:

Secure Clinching nuts are mostly made from strong, cold-formable steel alloys. Common ones are low or medium carbon steels like 1008, 1010, 1018, or alloy steels such as 10B21. For resisting rust, stainless steel grades like AISI 302, 304, 316 are often used. Which one you pick depends on how strong it needs to be, how well it can bend, and the conditions it will be in. The material has to be hard enough to push aside the sheet it's being put into, but also flexible enough to handle the high force of installation without breaking. That way, the Secure Clinching nut can form a tight, long-lasting hold.

Can Secure Clinching nuts be used with pre-painted or coated sheets?

Yeah, Secure Clinching nuts usually work okay with sheets that are already finished. The cold-forming process for clinching doesn’t mess up coatings with heat as much as welding does. But the high pressure right where the nut is might crack brittle paints under the nut’s flange.

Test your selected paint or coating to ensure it adheres well and looks satisfactory.