Robust Clinching nut

Send Inquiry

The core reason for their versatility lies in their robustness, allowing Robust Clinching nut to be used with a wide variety of ductile materials. In practice, they are commonly used with a wide variety of materials, including mild steel, aluminum alloys with various tempers, brass, pure copper, and some stainless steels—austenitic stainless steel being the most common.The material they’re being put into needs to be flexible enough to move when clinching without breaking. How thick the material is matters too. Each type of Robust Clinching nut has a range of thicknesses it works with, usually around 0.5mm to 6mm (0.020" to 0.236"), depending on the nut’s size and how strong the material is.

Product Advantages:

Using Robust Clinching nuts can save a lot of money. You don’t need welding equipment, people to run the welders, energy for welding, or the supplies that go with it—like the stuff to extract fumes and keep things safe.

Putting them in is really fast, too. With automated presses, each nut usually takes just a few seconds, which means you can make more in less time. You also use fewer parts—no need for washers or locknuts—so handling and keeping track of parts is simpler.

Compared to welding, there’s not much scrap left over. And since Robust Clinching nuts hold up well, you spend less on warranties and fixing mistakes. All that makes them a pretty cheap way to fasten things when you’re making a lot of them.

| Mon | 440-2 | 632-1 | 632-2 | 832-1 | 832-2 | 024-1 | 024-2 | 032-1 | 032-2 | 0420-1 | 0420-2 |

| P | 40 | 32 | 32 | 32 | 32 | 24 | 24 | 32 | 32 | 20 | 20 |

| d1 | #4 |

#6 |

#6 |

#8 |

#8 |

#10 |

#10 |

#10 |

#10 |

1/4 | 1/4 |

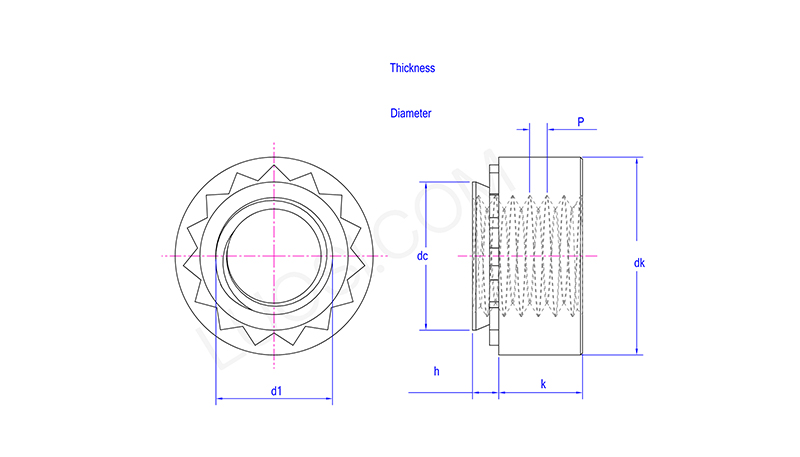

| dc max | 0.343 | 0.212 | 0.212 | 0.233 | 0.233 | 0.295 | 0.295 | 0.295 | 0.295 | 0.343 | 0.187 |

|

Diameter of mounting holes min |

0.344 | 0.213 | 0.213 | 0.234 | 0.234 | 0.296 | 0.296 | 0.296 | 0.296 | 0.344 | 0.1875 |

|

Diameter of mounting holes max |

0.347 | 0.216 | 0.216 | 0.237 | 0.237 | 0.299 | 0.299 | 0.299 | 0.299 | 0.347 | 0.1905 |

| dk max | 0.45 | 0.29 | 0.29 | 0.32 | 0.32 | 0.38 | 0.38 | 0.38 | 0.38 | 0.45 | 0.26 |

| dk min | 0.43 | 0.27 | 0.27 | 0.3 | 0.3 | 0.36 | 0.36 | 0.36 | 0.36 | 0.43 | 0.24 |

| h max | 0.087 | 0.038 | 0.054 | 0.038 | 0.054 | 0.038 | 0.054 | 0.038 | 0.054 | 0.12 | 0.038 |

| h coder | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 3 | 1 |

| k max | 0.18 | 0.1 | 0.1 | 0.14 | 0.14 | 0.17 | 0.17 | 0.17 | 0.17 | 0.18 | 0.1 |

| k min | 0.16 | 0.08 | 0.08 | 0.12 | 0.12 | 0.15 | 0.15 | 0.15 | 0.15 | 0.16 | 0.08 |

|

Thickness of mounting plate min |

0.091 | 0.04 | 0.056 | 0.04 | 0.056 | 0.04 | 0.056 | 0.04 | 0.056 | 0.125 | 0.04 |

Install the required equipment:

Installing a nut requires specific press equipment, typically a hydraulic or servo-electric press. A dedicated clinching tool (punch and die set) is mounted in the press, designed for the specific nut size and sheet thickness. The tool applies high, localized pressure to deform the sheet around the nut's serrated base.