Precision Engineered Hexagon Weld Nut

Send Inquiry

The material choice of Precision Engineered Hexagon Weld Nut lock washers has a direct impact on their performance. Steel or stainless steel is usually the main raw material, but there are significant differences in performance between different types of steel. For washers made of ordinary steel, their performance is largely determined by the carbon content. Steel with a lower carbon content is softer in texture and easier to process and shape. This feature brings convenience to the manufacturing process, can improve production efficiency and reduce processing difficulty. Medium carbon steel exhibits good comprehensive performance, achieving a good balance between strength and toughness, and is suitable for scenarios with certain requirements for both. Steels with a high carbon content have higher hardness but are also more brittle.

When it comes to stainless steel washers, you'll often see types like 304 or 316. These contain ingredients like chromium and nickel – ingredients that make them less prone to rust and more durable.

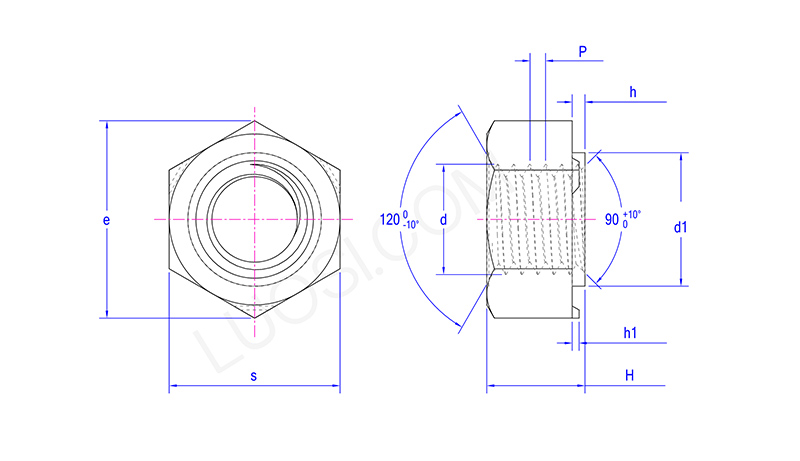

| Mon | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| d1 max | 4.47 | 5.97 | 6.96 | 7.96 | 10.45 | 12.45 | 14.75 | 16.75 | 18.735 |

| d1 min | 4.395 | 5.895 | 6.87 | 7.87 | 10.34 | 12.34 | 14.64 | 16.64 | 18.605 |

| e min | 8.15 | 9.83 | 10.95 | 12.02 | 15.38 | 18.74 | 20.91 | 24.27 | 26.51 |

| h max | 0.55 | 0.65 | 0.7 | 0.75 | 0.9 | 1.15 | 1.4 | 1.8 | 1.8 |

| h min | 0.45 | 0.55 | 0.6 | 0.6 | 0.75 | 0.95 | 0.8 | 1 | 1 |

| h1 max | 0.25 | 0.35 | 0.4 | 0.4 | 0.5 | 0.65 | 0.8 | 1 | 1 |

| h1 min | 0.15 | 0.25 | 0.3 | 0.3 | 0.35 | 0.5 | 0.6 | 0.8 | 0.8 |

| s max | 7.5 | 9 | 10 | 11 | 14 | 17 | 19 | 22 | 24 |

| s min | 7.28 | 8.78 | 9.78 | 10.73 | 13.73 | 16.73 | 18.67 | 21.67 | 23.67 |

| H max | 3 | 3.5 | 4 | 5 | 6.5 | 8 | 10 | 11 | 13 |

| H min | 2.75 | 3.2 | 3.7 | 4.7 | 6.14 | 7.64 | 9.64 | 10.57 | 12.57 |

Product Details

Putting in a Precision Engineered Hexagon Weld Nut takes the right tools and some practice. First, clean off the nut and the metal where it’s going—that helps the weld hold better. Usually, you use a welder that runs electricity through both parts. The resistance heats everything up, melting those little bumps on the nut so it sticks to the metal. You’ve also got to press down with the right amount of force while welding to make sure it seals evenly. Some nuts come with a small tab or guide that makes positioning way easier.

Q: What surface treatments do you offer for Precision Engineered Hexagon Weld Nuts?

A:Our hex weld nuts have a few different coatings to help with rust. For decent rust protection during storage or regular use, we often zinc plate them. You can get that in clear, blue, or yellow. If you need something heavier duty, hot-dip galvanizing puts on a much thicker layer of zinc. There’s also black oxide—it gives it a dark finish and a bit of rust protection. For stainless steel nuts, we often use passivation to keep their rust resistance intact. So just choose based on where your project’s going to be used.