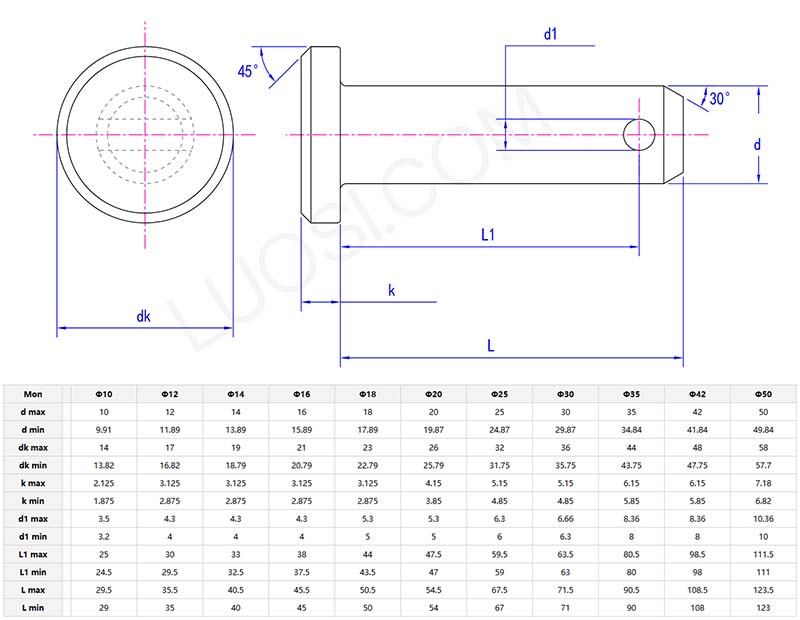

Pin Shafts

Send Inquiry

Pin shafts are made from good-quality materials like carbon steel, stainless steel, and titanium,each has its own perks. Carbon steel ones get heat-treated to make them harder, which is great for industrial machines that need tough parts. Stainless steel clevis pins resist rust really well, so they’re perfect for places that are wet, like marine setups, or around chemicals. Titanium alloy parts are strong and light. Aircraft parts have relatively high weight requirements, so titanium alloy materials are more suitable.

Some materials might have nickel or chrome coatings to help them last longer and stand up to wear. The material you pick affects how much weight the pin can handle, what kinds of environments it can work in, and how long it’ll last. So you need to choose the right one for where and how you’re using it.

Features

The weight pin shafts can handle depends on two things: the material’s strength (how much it can bend before breaking) and the area where it might shear (split apart). Grade 8 steel pins, for example, can take up to 150,000 PSI of shear stress. Titanium pins are good because they’re strong but light.

Engineers figure out what diameter pin they need by using safety factors-usually 2:1, meaning the pin should hold twice the expected load, whether it’s steady or changing. When loads are repeated a lot (like in moving parts), making sure the pin resists fatigue is key. Treatments like shot peening (blasting tiny particles to strengthen the surface) or cryogenic processing (freezing to improve structure) help the metal stay tough at a microscopic level.

Certifications from standards like MIL-SPEC or ASTM F468 make sure the pins meet industry stress limits, so you know they’re safe for what you need them for.

How to handle extreme loads or shock impacts?

Our pin shafts get tested for fatigue and how much they can pull or stretch to make sure they hold weight well,they’re often rated for over 10,000 cycles when there’s moving stress. If you’re using them for heavy stuff like mining machines or marine equipment, we suggest forged steel pins. These have stronger shear points or built-in locks (like cotter pins) to stay secure.

The technical sheets show the max loads they can handle,both pushing and pulling forces,to keep things safe. We can also add coatings that fight vibration or extra locking features so the pins don’t come loose by accident.