Un 400 Stainless Steel Guide Pin

Send Inquiry

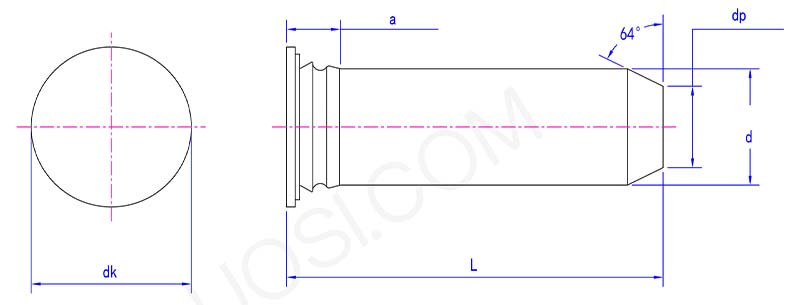

The UN 400 stainless steel guide pin is a precision-made positioning part, designed for tough industrial uses where you need both corrosion resistance and strength. It follows standard "UN" specs (which basically mean consistent sizes), and it’s a key alignment tool in jigs, fixtures, molds, and automated machines.

Unlike carbon steel guide pins, the 400 series stainless steel guide pin ones don’t rust or oxidize easily when they get exposed to moisture, chemicals, or the air. That makes them work well in harsher environments while still keeping the guiding accuracy and durability under load. So whether it’s damp conditions, chemical setups, or just regular industrial use, these pins hold up without losing their shape or alignment,pretty much a go-to when you need reliable performance in rough settings.

Mon

0.125

0.187

0.25

a max

0.09

0.09

0.09

d max

0.127

0.189

0.252

d min

0.123

0.185

0.248

dk max

0.22

0.285

0.35

dk min

0.19

0.255

0.32

dp max

0.096

0.138

0.183

dp min

0.084

0.126

0.171

Advantages

The UN 400 stainless steel guide pin has some key upsides. First off, it’s naturally corrosion-resistant, so in a lot of environments you don’t need to plate it right away. Plus, you can heat-treat it to get good mechanical properties. That makes it a solid choice where you need both decent wear resistance and rust protection without breaking the bank.

The "UN" standard sizes are a big plus,they make these pins easy to swap out and source, which is handy. They work well in washdown setups, like in food or pharma, since they don’t rust easily. That cuts down on maintenance too. And they hold their shape well, so they’re a durable option that lasts a long time. Basically, if you need a guide pin that can handle moisture, resist rust, and stay reliable under load, these stainless steel ones are a practical pick.

Corrosion resistant

The UN 400 stainless steel guide pin holds up well against rust in non-harsh atmospheres, steam, and lots of mild chemical setups. Though they aren’t as rust-proof as 300 Series types like 304 or 316 in really tough corrosive conditions, these 400 Series pins offer solid value and enough protection for many industrial uses,especially when you need both high strength and hardness. They also fight off oxidation pretty well at high heat. Basically, if you don’t need top-tier corrosion resistance but want a durable guide pin that can handle strength demands, these work great without breaking the bank.