Permanently Locking Two Fold Self Locking Washers

Send Inquiry

Permanently Locking Two fold self locking washers can have different surface treatments to make them more resistant to rust, look better, or work more smoothly. Common ones include zinc plating—like yellow, clear, or black oxide coatings. These often have extra chromate treatments to help fight rust even more. Phosphate coatings make them slide better and help paint stick to them. These surface treatments protect the steel underneath without messing up how well the washers lock things down.

| Mon |

Φ6 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

Φ18 |

Φ20 |

Φ22 |

Φ24 |

Φ27 |

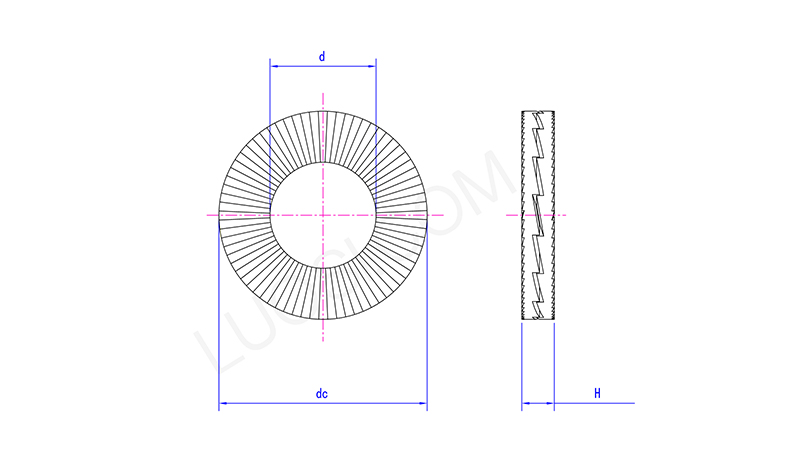

| d max | 6.6 | 8.8 | 10.9 | 13.2 | 15.4 | 17.2 | 19.7 | 21.6 | 23.6 | 25.5 | 28.6 |

| d min | 6.3 | 8.6 | 10.5 | 12.8 | 15 | 16.8 | 19.3 | 21.2 | 23.2 | 25.1 | 28.2 |

| dc max | 11 | 13.7 | 16.8 | 19.7 | 23.2 | 25.6 | 29.2 | 30.9 | 34.7 | 39.2 | 42.3 |

| dc min | 10.6 | 13.3 | 16.4 | 19.3 | 22.8 | 25.2 | 28.8 | 30.5 | 34.3 | 38.8 | 41.7 |

| H max | 2.45 | 2.25 | 2.25 | 2.25 | 3.25 | 3.25 | 3.45 | 3.25 | 3.45 | 3.45 | 6.8 |

| H min | 1.95 | 1.75 | 1.75 | 1.75 | 2.75 | 2.75 | 2.95 | 2.75 | 2.95 | 2.95 | 6.3 |

Advantage:

In some uses, it helps to have permanently locking two fold self locking washers with dry film lubricants on them—like ones made with PTFE or molybdenum disulfide. These coatings make it easier to put them in by reducing friction. That means you can get more consistent and accurate tightness when installing them. And they still let the washer's little ridges and tabs work like they should. Washers with this kind of lubrication are good for when you need precise assembly or when you might need to reuse them.

What specific material grades and coatings are available for your permanently locking two fold self locking washers for corrosive environments?

Our regular permanently locking two fold self locking washers are made of carbon steel with a zinc coating. If you need them to resist rust better, we have options like A2/A4 (304/316) stainless steel. There are extra coatings too—like Geomet, which is better for the environment, Dacromet, and you can get PTFE seals if you want. We pick materials that make sure the washers still lock things properly even when conditions are rough.