Permanent Clinching Nut

Send Inquiry

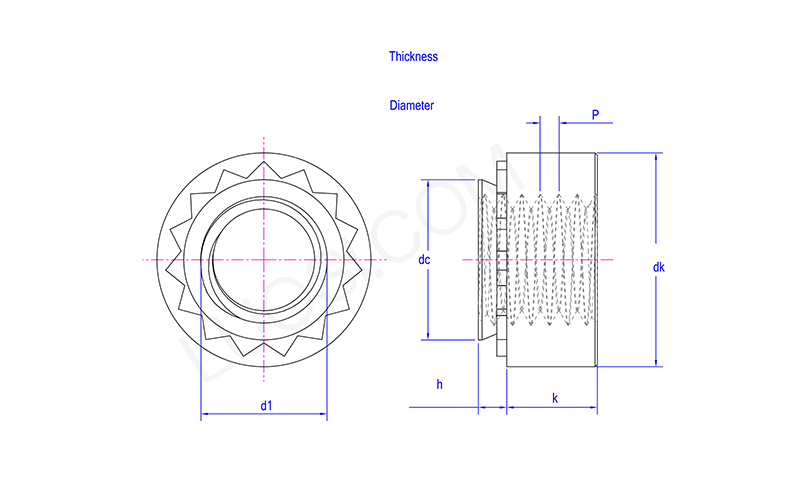

A Permanent Clinching nut is a permanent fastener used for sheet metal. Unlike regular nuts that need welding or threading, it can be installed quickly with press force, creating a strong, reliable threaded spot to attach things. It has a precisely made pilot and a knurled shank. When installed, these parts move the material they're being put into, forming a lock.

This avoids thermal deformation, eliminates additional steps, and significantly reduces assembly time and costs. This technology is ideal for high-volume production requiring efficient and robust fastening solutions and is used in a wide range of industries.

Product Benefits:

The main thing about a Permanent Clinching nut is that it can form a permanent, strong connection directly in ductile sheet metal or non-ferrous plates without needing pre-drilled threads. When you install it, a press pushes the Permanent Clinching nut into the material. Its specific shape makes the metal around it move and flow into a ring-shaped indent (like a knurl or groove) under the head and/or around the shank.

The resulting strong mechanical lock effectively resists rotational and pull-out forces. This technology also produces a high-strength thread insert that is resistant to vibration, providing a strong and reliable foundation for the bolt connection.

| Mon | M2-1 | M2-2 | M3-1 | M3-2 | M3.5-1 | M3.5-2 | M4-1 | M4-2 | M5-1 | M5-2 | M6-1 |

| P | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.7 | 0.7 | 0.8 | 0.8 | 1 |

| dc max | 4.22 | 4.22 | 4.73 | 4.73 | 5.38 | 5.38 | 5.97 | 5.97 | 7.47 | 7.47 | 8.72 |

| dk min | 6.05 | 6.05 | 6.05 | 6.05 | 6.85 | 6.85 | 7.65 | 7.65 | 9.25 | 9.25 | 11.3 |

| dk max | 6.55 | 6.55 | 6.55 | 6.55 | 7.35 | 7.35 | 8.15 | 8.15 | 9.75 | 9.75 | 11.8 |

| k min | 1.25 | 1.25 | 1.75 | 1.75 | 1.75 | 1.75 | 2.75 | 2.75 | 3.55 | 3.55 | 3.83 |

| k max | 1.75 | 1.75 | 2.25 | 2.25 | 2.25 | 2.25 | 3.25 | 3.25 | 4.05 | 4.05 | 4.33 |

| h coder | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 |

| h max | 0.98 | 1.38 | 0.98 | 1.38 | 0.98 | 1.38 | 0.98 | 1.38 | 0.98 | 1.38 | 1.38 |

| Thickness Of Mounting Plate Min | 1 | 1.4 | 1 | 1.4 | 1 | 1.4 | 1 | 1.4 | 1 | 1.4 | 1.4 |

|

Diameter Of Mounting Holes Min |

4.25 | 4.25 | 4.75 | 4.75 | 5.4 | 5.4 | 6 | 6 | 7.5 | 7.5 | 8.75 |

|

Diameter Of Mounting Holes Max |

4.33 | 4.33 | 4.83 | 4.83 | 5.48 | 5.48 | 6.08 | 6.08 | 7.58 | 7.58 | 8.83 |

| d1 | M2 | M2 | M3 | M3 | M3.5 | M3.6 | M4 | M4 | M5 | M5 | M6 |

What are the main failure modes for Permanent Clinching nuts?

Permanent Clinching nuts can fail in a few main ways. One is pull-out—when the nut comes straight out of the sheet. That often happens if the clinch isn’t deep enough or if the nut isn’t the right one for the sheet’s thickness. Another is spinning—when the nut turns in the sheet, usually because the serrations aren’t gripping well enough. The threads inside can also strip.

Picking the right nut and setting the installation up correctly keeps these problems from happening.