Integrated Flange Hexalobular Head Flange Bolts

Send Inquiry

The Integrated Flange Hexalobular Head Flange Bolts have different quality certifications, indicating that they comply with international standards. Such entities generally obtain ISO 9001 certification to regulate quality management, and ISO 14001 certification to implement environmental responsibility requirements. In terms of quality and technical specifications, the automotive sector uses IATF 16949 as the core compliance basis, while the construction sector mostly uses ASTM A325 (focusing on high-strength bolts) as the compliance benchmark.

Many suppliers can also provide bolts that meet the requirements - they have the European CE mark and pass the RoHS standard. These bolts contain no harmful substances like lead and mercury, and are certified as safe and reliable, so they can be used in regulated industries around the world.

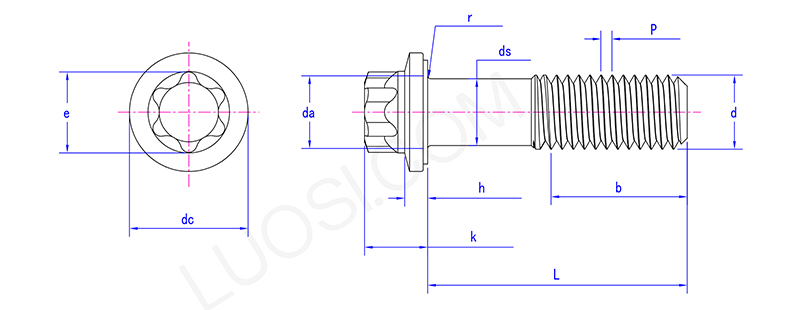

| Mon | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 |

| P | 0.7 | 0.8 | 1 | 1|1.25 | 1|1.25|1.5 | 1.25|1.5|1.75 | 1.5|2 | 1.5|2 | 1.5|2|2.5 | 1.5|2|2.5 |

| da max | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 |

| dc min | 7.88 | 8.88 | 10.88 | 13.73 | 16.83 | 18.83 | 21.93 | 25.09 | 28.04 | 31.09 |

| ds | 3.55 | 4.48 | 5.35 | 7.19 | 9.03 | 10.86 | 12.70 | 14.70 | 16.38 | 18.38 |

| e | 4.6 | 5.55 | 7.3 | 9.2 | 10.95 | 12.65 | 16.4 | 18.15 | 21.85 | 21.85 |

| k max | 4.5 | 5.5 | 6.5 | 8.2 | 10 | 12 | 14 | 16 | 18 | 20 |

| k min | 4.25 | 5.25 | 6.25 | 7.95 | 9.75 | 11.75 | 13.75 | 15.75 | 17.75 | 19.75 |

| r min | 0.2 | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

| h min | 1.05 | 1.45 | 1.55 | 2.25 | 2.95 | 3.6 | 3.9 | 4.8 | 4.9 | 6.2 |

| h max | 1.3 | 1.7 | 1.8 | 2.5 | 3.2 | 3.9 | 4.2 | 5.1 | 5.2 | 6.5 |

Product Details

When engaging in wind power generation and installing solar panels, Integrated Flange Hexalobular Head Flange Bolts are often used. Its purpose is very simple, which is to fix the components on the equipment. This product is designed with high-strength fastening force bearing capacity, and is equipped with anti-rust coatings such as zinc-nickel, so it can easily cope with complex outdoor scenes, including severe weather erosion and frequent temperature changes.

The built-in flange can distribute the pressure evenly across surfaces such as tower flanges or panel frames, which helps maintain stability over the long term. Clean energy has been advancing. These bolts are reliable and can ensure the safety and stability of renewable energy facilities. Now more and more people are willing to use them.

Application Scenario

Integrated Flange Hexalobular Head Flange Bolts are commonly used in various fields such as automobiles, aerospace, machinery, and construction. In the automotive field, its design can effectively prevent threads from loosening and ensure the stable installation of engine and chassis components. In the aerospace industry, they are used because they can withstand large torques well and are highly trusted at critical connection points. Manufacturers of machinery prefer this built-in flange because it can speed up the assembly process. In the construction field, they are used in places that require clamping fixation. The reason for choosing this type of bolt in all these applications is that they are sturdy, efficient, and unlikely to loosen due to vibration.