Inch Hexagon Thick Nuts

Send Inquiry

The "thick" means that Inch hexagon thick nuts are taller than standard nuts, thereby providing a larger thread meshing space to withstand heavy loads. They are made of carbon steel and stainless steel and are used to clamp machinery, construction joints or industrial equipment without stripping.

Product details and parameters

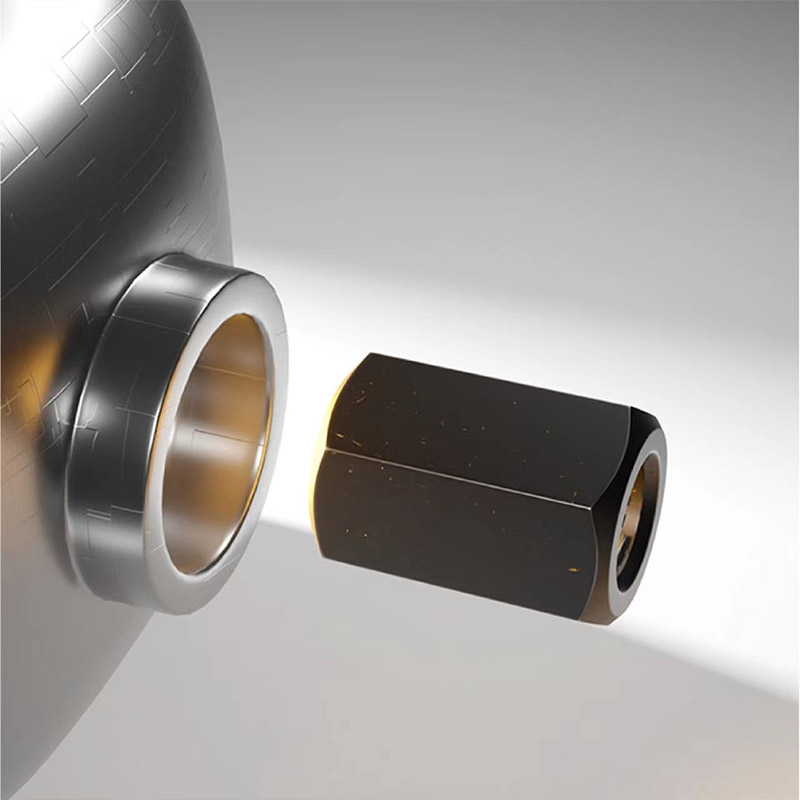

Inch hexagon thick nuts are used where vibration or heavy pressure may cause ordinary nuts to loosen. For example, agricultural equipment, truck frames or old-fashioned machinery that still uses imperial bolts. Their thickness helps to disperse force and reduces wear and tear on softer materials such as aluminium or wood. They are also very common in traditional systems where metric nuts are not applicable. Professional tip: Use them in combination with bolts of matching grades (such as grade 5 or grade 8).

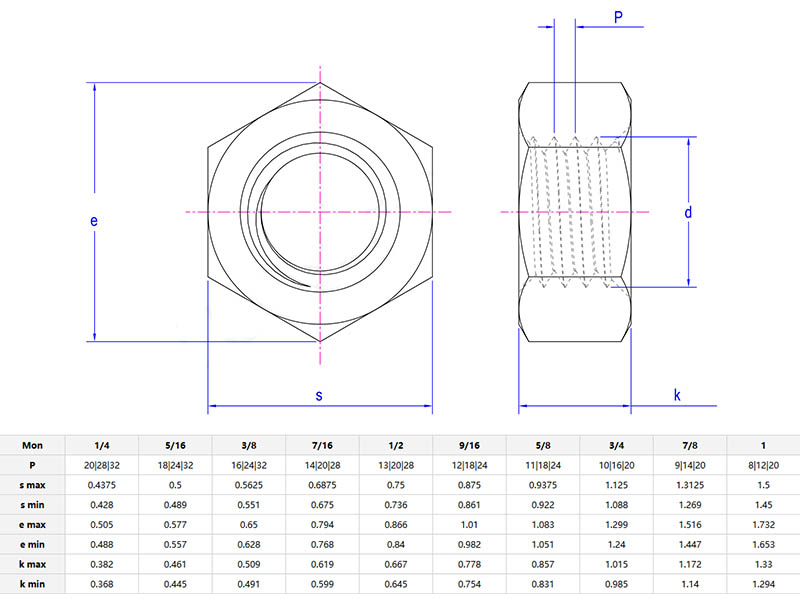

When choosing the appropriate Inch hexagon thick nuts, the diameter of the bolt should be considered first. Select the appropriate nut size (for example, ½ "-13 indicates a bolt with a diameter of ½" and 13 threads per inch). Pitch is also very important. UNC (thick) indicates general-purpose, and UNF (thin) indicates precision. The height of the nut should be approximately 1.5 times the diameter of the bolt. Before tightening, it is essential to conduct a test fit. Forcing the use of mismatched threads will damage the nut and bolt.

Inch hexagon thick nuts are used where building codes require high-strength fasteners, such as steel beam connections or the bases of wind turbines. Its flat bearing surface ensures stable contact with the joint. Strictly adhere to the torque specification, as too loose it will lead to failure, and too tight it will cause thread wear. Check for cracks or thread damage before installation.

Thick Nuts vs. Standard Nuts

Why choose Inch hexagon thick nuts instead of ordinary nuts? Standard nuts are thinner and tend to slip easily under heavy loads. Thick nuts have additional materials to clamp the bolts more tightly, especially in high-vibration devices such as engines or conveyor belts. Because the threads are deeper, they are also less likely to be wrongly fastened. Standard nuts are used for light-load operations (such as furniture). When high strength is required, they should be upgraded to thick nuts.