High Strength Hexagon Weld Nut

Send Inquiry

Manufacturers of High Strength Hexagon Weld Nut must produce according to industry standards so that the strength, precision and welding quality of the nuts can meet the standards. They also mean nuts from different suppliers are often interchangeable. For example, DIN standards define things like exact sizes, materials, and strength requirements. ISO standards help keep quality consistent internationally. ASTM standards focus more on testing methods and material specs. When companies follow these rules, their nuts can be used in various applications and easily replaced with other compliant parts.

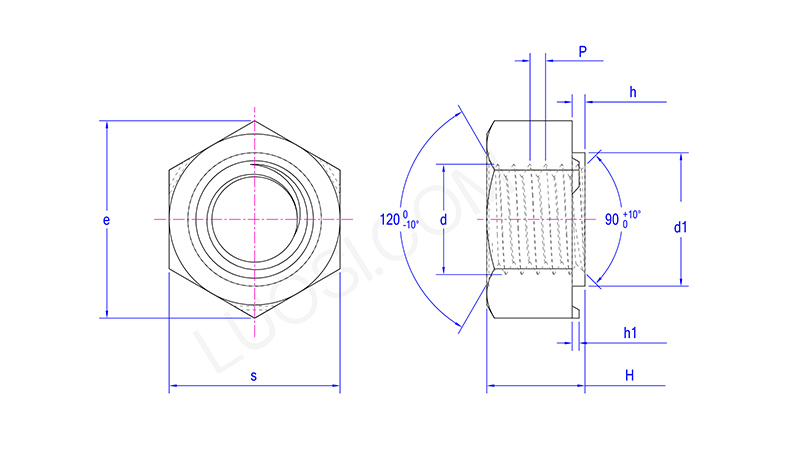

Product details

Down the road, High Strength Hexagon Weld Nut tech will probably keep getting better. Manufacturers might test out new materials or mixes to help them work even better—maybe by developing alloys that are stronger and resist rust more. We could also see tweaks to the shape of the weld points or the nut body to make welding cleaner and support heavier loads. As welding methods improve, it’s possible to produce better quality nuts at a lower cost. Updates like these should help hex weld nuts stay useful and reliable across different industries.

Q:How are High Strength Hexagon Weld Nuts packaged for shipping?

A:We pack hex weld nuts to keep them safe during shipping. For larger orders, we use standardized packaging: thickened cardboard boxes or high-strength sealed bags are used for the outer layer. The material's tensile strength and sealing properties block moisture and cushion external impacts. After packaging, the goods are manually calibrated and mechanically assisted to be stably stacked on non-slip pallets, equipped with buffer partitions and secured with strapping. Whether transported by road or sea, they can be stacked securely. The dual protection of "material protection + stacking reinforcemen

| Mon | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.5 | 0.7 | 0.8 | 1 | 1丨1.25 | 1丨1.25丨1.5 | 1.25丨1.5丨1.75 | 1.5丨2 | 1.5丨2 |

| d1 max | 4.47 | 5.97 | 6.96 | 7.96 | 10.45 | 12.45 | 14.75 | 16.75 | 18.735 |

| d1 min | 4.395 | 5.895 | 6.87 | 7.87 | 10.34 | 12.34 | 14.64 | 16.64 | 18.605 |

| e min | 8.15 | 9.83 | 10.95 | 12.02 | 15.38 | 18.74 | 20.91 | 24.27 | 26.51 |

| h max | 0.55 | 0.65 | 0.7 | 0.75 | 0.9 | 1.15 | 1.4 | 1.8 | 1.8 |

| h min | 0.45 | 0.55 | 0.6 | 0.6 | 0.75 | 0.95 | 1.2 | 1.6 | 1.6 |

| h1 max | 0.25 | 0.35 | 0.4 | 0.4 | 0.5 | 0.65 | 0.8 | 1 | 1 |

| h1 min | 0.15 | 0.25 | 0.3 | 0.3 | 0.35 | 0.5 | 0.6 | 0.8 | 0.8 |

| s max | 7.5 | 9 | 10 | 11 | 14 | 17 | 19 | 22 | 24 |

| s min | 7.28 | 8.78 | 9.78 | 10.73 | 13.73 | 16.73 | 18.67 | 21.67 | 23.67 |

| H max | 3 | 3.5 | 4 | 5 | 6.5 | 8 | 10 | 11 | 13 |

| H min | 2.75 | 3.2 | 3.7 | 4.7 | 6.14 | 7.64 | 9.64 | 10.57 | 12.57 |