Hex Flange Screw

Send Inquiry

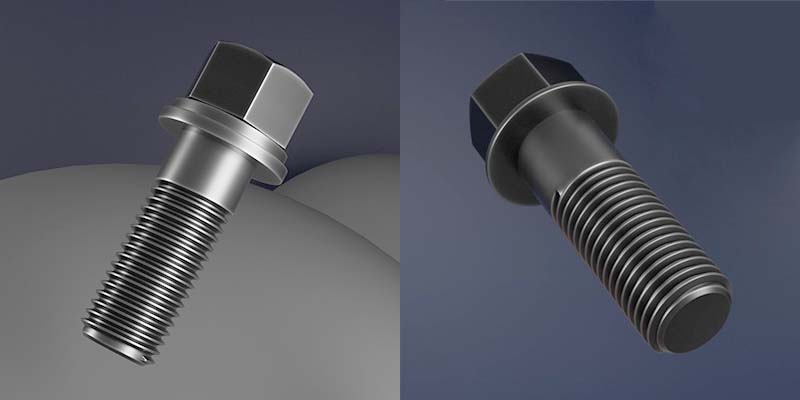

The hex flange screw has a hexagonal head, and there is a disc-shaped flange surface below its head. This flange can make the screw more stable when fixing things and prevent it from loosening easily. It is used in various places that require a firm connection.

Hexagon flange screws have a larger contact area with the connection surface than ordinary hexagonal bolts, so the stress is not concentrated but dispersed, which reduces the deformation and damage of the connection surface. The flange increases the friction and reduces the looseness. The installation is simple, no gasket is required, and there are fewer accessories. The structure of hexagonal bolts with flanges is more stable than that of ordinary bolts. The flange surface increases the contact area and disperses the stress.

Features

Hex flange screws can be used to assemble toys, especially some large toys made of metal or plastic. It can firmly connect all the parts of the toy. When children play, if they pull or drop hard, the toy is less likely to fall apart and is safer.

Hexagonal flange screws can be used to fix the components of bicycles, such as pedals, handlebars, shelves, etc. During the cycling process, bicycles will encounter bumps and vibrations. Using them can ensure that the parts do not loosen or fall off. Protect the cycling safety of cyclists.

Hexagon flange screws can also be used to install household lamps, such as chandeliers, ceiling lamps, etc. It can firmly fix the lamp to the ceiling. The flange can evenly distribute the weight of the lamp, so you don't need to worry about the screws loosening.

Product selling point

Hex flange screws combine the dual functions of screws and washers, which can reduce the use of additional washers. During the assembly process, the operating steps are simplified, the assembly efficiency is improved, the labor cost and time cost are saved, the operation efficiency of the production line can be improved, and the delivery speed of the product can be accelerated.

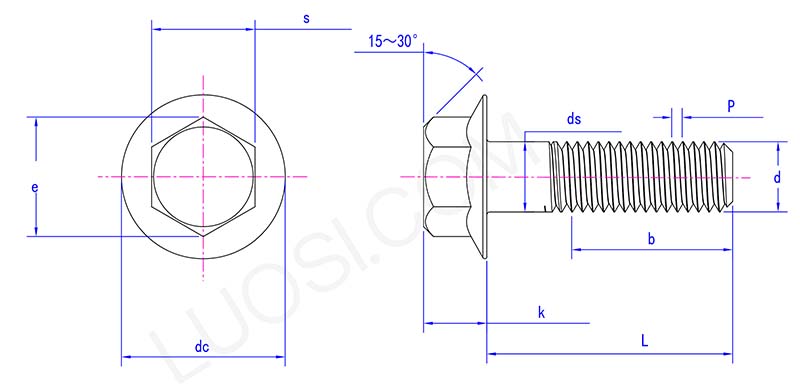

Mon

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

P

20|28|32

18|24|32

16|24|32

14|20|28

13|20|28

12|18|24

11|18|24

10|16|20

ds max

0.25

0.3125

0.375

0.4375

0.5

0.5625

0.625

0.75

ds min

0.245

0.3065

0.396

0.4305

0.493

0.5545

0.617

0.741

s max

0.375

0.5

0.5625

0.625

0.75

0.8125

0.9375

1.125

s min

0.367

0.489

0.551

0.612

0.736

0.798

0.922

1.1

e max

0.433

0.577

0.65

0.722

0.866

0.938

1.083

1.299

e min

0.409

0.548

0.618

0.685

0.825

0.895

1.034

1.234

dc max

0.56

0.68

0.81

0.93

1.07

1.19

1.33

1.59

k max

0.28

0.32

0.39

0.46

0.51

0.57

0.62

0.73