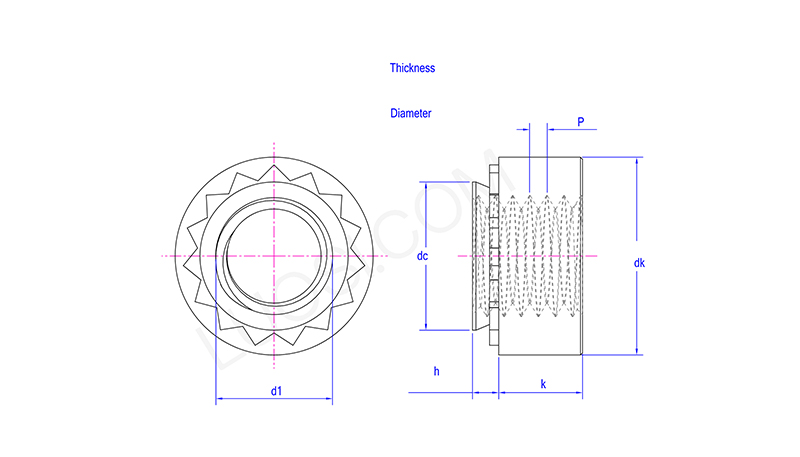

Flush Mounting Clinching Nut

Send Inquiry

To make sure flush mounting clinching nuts stay properly connected, you need to do specific quality checks. A quick visual look can tell if the nut is seated right—like if it's flush or sitting square.

Important tests include measuring how much force it takes to push or pull the nut out, to make sure the clinch is strong enough. Torque tests check if the threads are in good shape and won't strip. Cutting a sample to look at the cross-section lets you see if the material has fully filled the clinch grooves.

Watching the press tonnage while installing gives you real-time control over the process. Keeping Flush-Mounting Clinching nut quality consistent depends on having materials with controlled properties, precise tools, and the right press settings.

| Mon | 632-2 | 632-3 | 832-0 | 832-1 | 832-2 | 832-3 | 024-0 | 024-1 | 024-2 | 024-3 | 032-0 |

| P | 32 | 32 | 32 | 32 | 32 | 32 | 24 | 24 | 24 | 24 | 32 |

| d1 | #6 |

#6 |

#8 |

#8 |

#8 |

#8 |

#10 |

#10 |

#10 |

#10 |

#10 |

| dc max | 0.187 | 0.187 | 0.212 | 0.212 | 0.212 | 0.212 | 0.249 | 0.249 | 0.249 | 0.249 | 0.249 |

|

Diameter of mounting holes min |

0.1875 | 0.1875 | 0.213 | 0.213 | 0.213 | 0.213 | 0.25 | 0.25 |

0.25 |

0.25 |

0.25 |

|

Diameter of mounting holes max |

0.1905 | 0.1905 | 0.216 |

0.216 |

0.216 |

0.216 |

0.253 |

0.253 |

0.253 |

0.253 |

0.253 |

| dk min | 0.27 | 0.27 | 0.3 | 0.3 | 0.3 | 0.3 | 0.33 |

0.33 |

0.33 |

0.33 |

0.33 |

| dk max | 0.29 | 0.29 | 0.32 |

0.32 |

0.32 |

0.32 |

0.35 |

0.35 |

0.35 |

0.35 |

0.35 |

| h max | 0.054 | 0.087 | 0.03 | 0.038 | 0.054 | 0.087 | 0.03 | 0.038 | 0.054 | 0.087 | 0.03 |

| h coder | 2 | 3 | 0 | 1 | 2 | 3 | 0 | 1 | 2 | 3 | 0 |

| k max | 0.08 | 0.08 | 0.1 | 0.1 | 0.1 | 0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

| k min | 0.06 | 0.06 | 0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

|

Thickness of mounting plate min |

0.056 | 0.091 | 0.03 | 0.04 | 0.056 | 0.091 | 0.03 | 0.04 | 0.056 | 0.091 | 0.03 |

Precautions:

Once a flush mounting clinching nut is installed, it doesn't need much special upkeep. Most of the care goes into the bolt that screws into it: make sure you use the right amount of force when putting it together or taking it apart. If they say to, use the right lubricants or anti-seize stuff, but stay away from anything that might cause stress corrosion cracking—especially with stainless steel.

Don't use too much force, or you might strip the threads. The flush mounting clinching nut itself is pretty tough since it's locked in place mechanically and often treated to resist rust. If it gets damaged, you usually have to drill it out and put a new one in a different spot.

Main Materials:

The material selection of plug-in rivet nuts is diverse. Their core materials are usually various types of steel, including carbon steel, stainless steel (such as the common 304 stainless steel or 316 stainless steel), etc.; in specific scenarios, brass or aluminum are also used as manufacturing materials.To further improve the rust resistance, steel rivet nuts are usually surface treated. Common coating processes include galvanizing to enhance their corrosion resistance in complex environments.