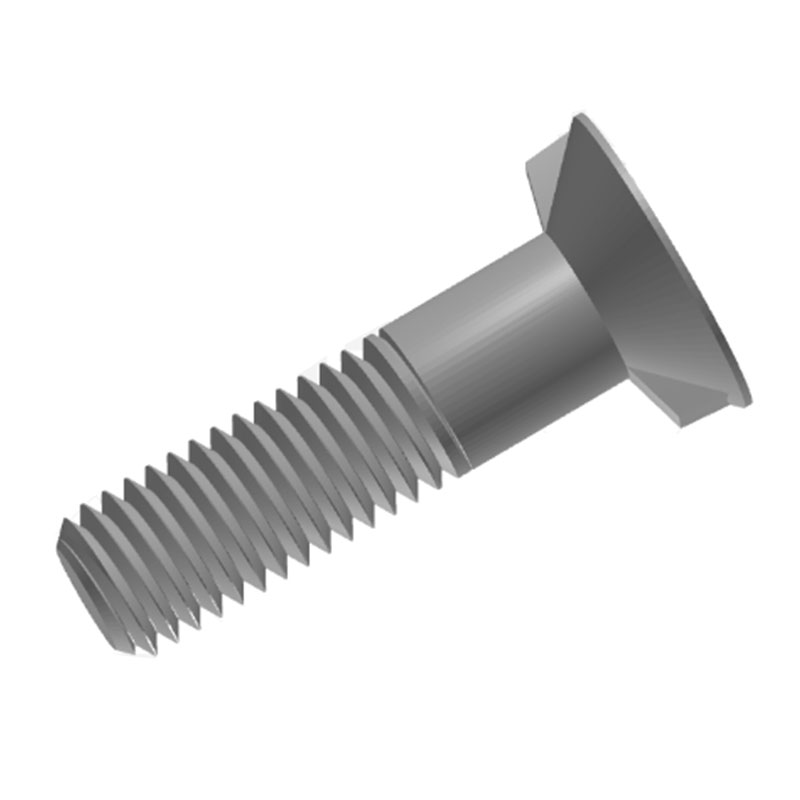

Flat countersunk nib bolt

Send Inquiry

The head of the flat countersunk nib bolt is flat. After installation, it can be flush with the surface of the connector. They have no protrusions and will not affect the appearance. There is a reverse protruding key block below the bolt head, which can be precisely inserted into the groove.

Product details

The bolt can hold the concave metal and is often used to repair steel Bridges that have been corroded underground. The reverse key can be locked in the uneven hole to prevent the bolt from peeling off. Because it has a flat head, it can effectively prevent the accumulation of salt/debris.

The flat countersunk nib bolt can withstand continuous vibration, so they are often used to install vibrators in silos. During all-weather operation, the key pins can be fixed on the steel plate. The flat head design does not accumulate grain dust. They are moisture-resistant and won't get stuck.

The bolt is widely used. It can be used to fix the cover plate of the car engine. When the engine is running, it will generate strong vibrations. The key block can be stuck in the groove between the cover plate and the engine housing to prevent the bolt from rotating and ensure that the cover plate is always tightly fixed to avoid dust and debris entering the engine compartment.

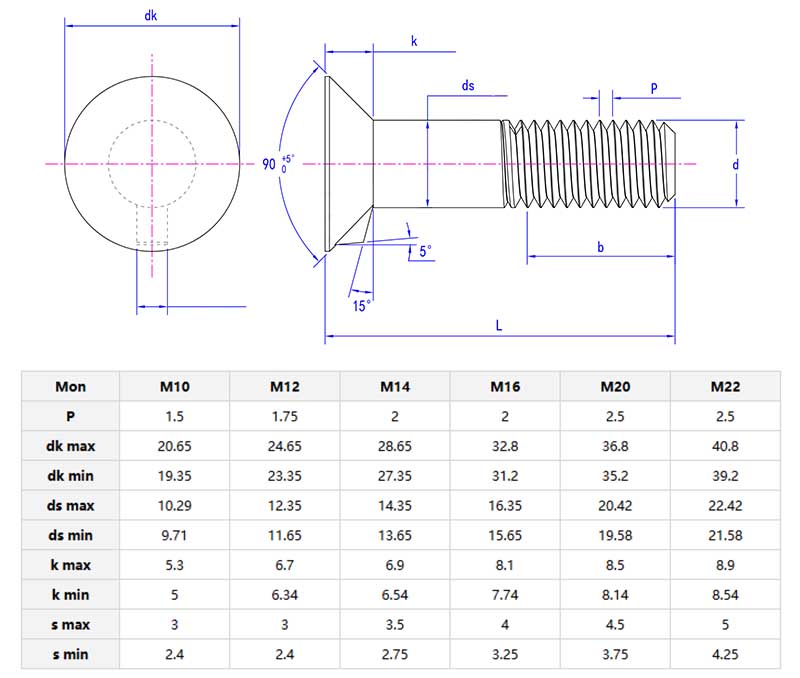

Product parameters

Product feature

The most prominent feature of the flat countersunk nib bolt is the reverse key anti-reverse structure. When installing the brackets for outdoor billboards, workers only need to align the key blocks of the bolts with the grooves of the brackets and insert them, then tighten the nuts. During the process, the bolts will not shift, which greatly improves the installation efficiency.