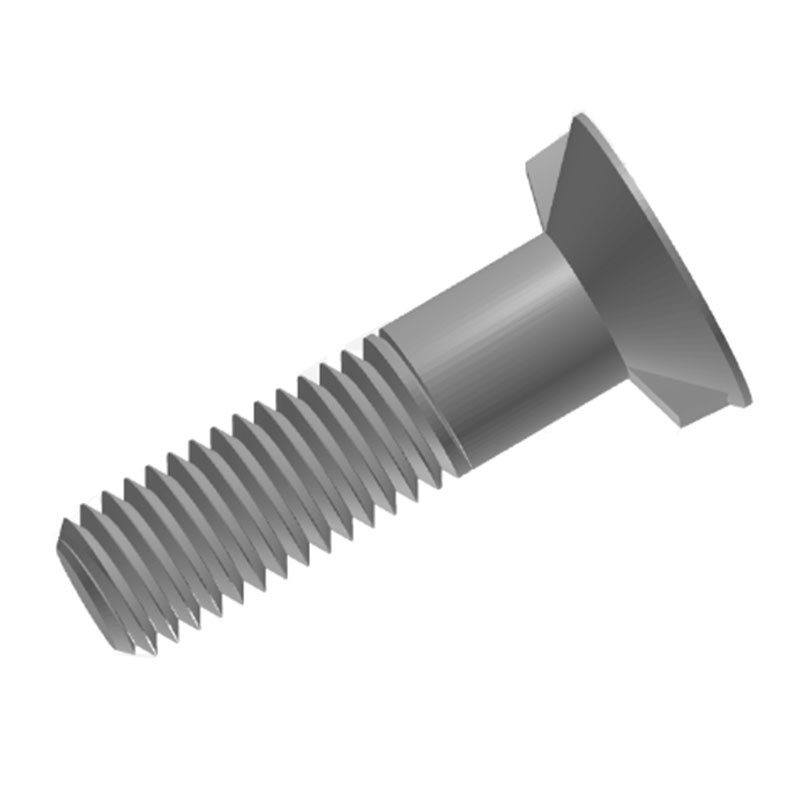

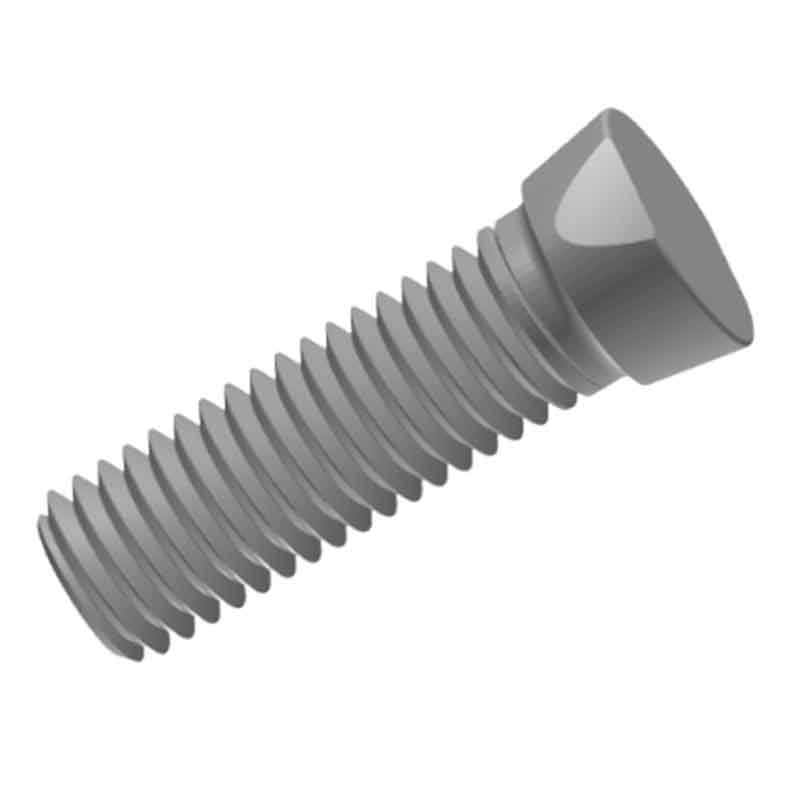

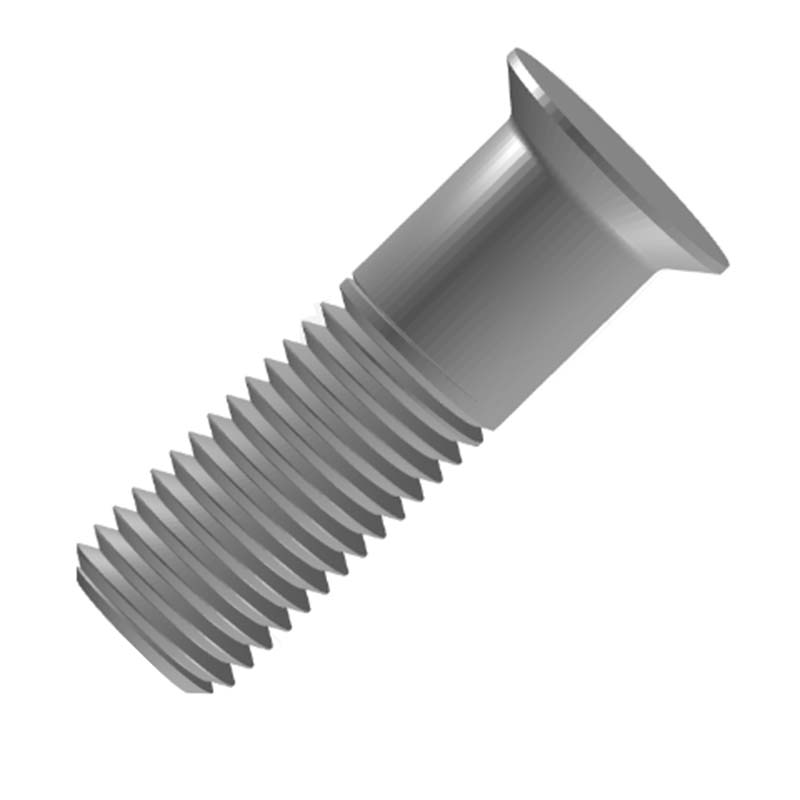

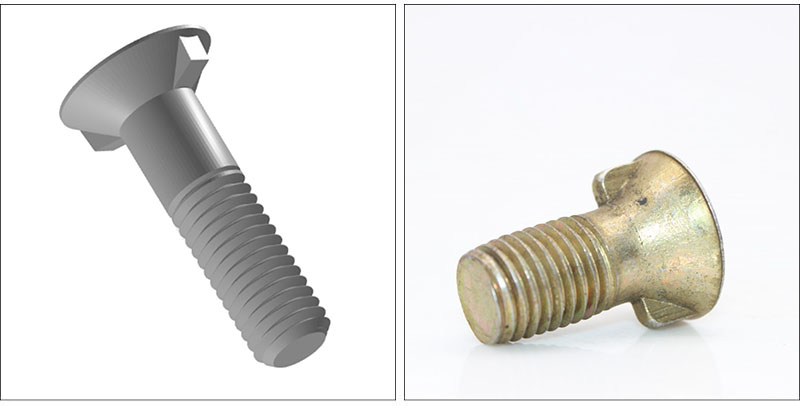

Countersunk head bolts with double nibs

Send Inquiry

Countersunk head bolts with double nibs are different from ordinary bolts. They have two small tenons under the head, like two small buckles, which can be stuck in the corresponding grooves. The screw part has standard threads and can be tightened with nuts.

Product details

They are used in the heavy machinery manufacturing industry. For example, in the manufacture of the boom and dipper joint of the excavator, the equipment is subjected to huge pressure and vibration during operation. The two tenons of the countersunk head bolts with double nibs can be firmly stuck in the corresponding grooves to prevent the bolts from rotating or loosening, ensuring the stability of the boom and dipper joint.

This bolt ensure that the connection is firmly fixed. Harbor crane installation Harbor cranes need to lift tons of cargo and use them for connection. The double nib structure can withstand huge tension and torque and prevent the bolts from loosening. They ensure safe port operations.

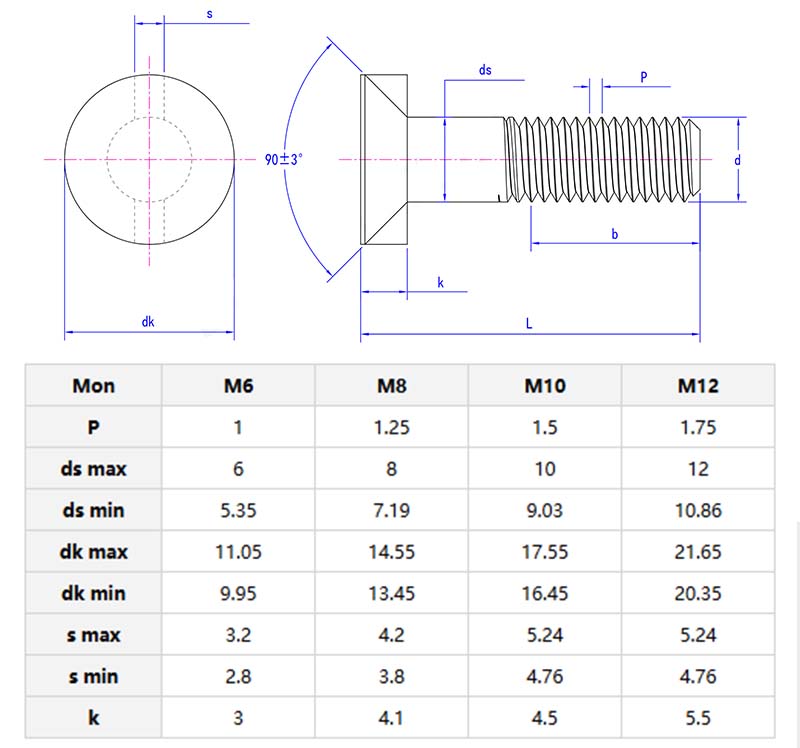

Product parameters

Product Features

The most prominent feature of Countersunk head bolts with double nibs is their double tenon structure. When installing the internal parts of the mine crusher, the crusher vibrates violently during operation, and the ordinary bolts are prone to loosening. The two tenons can fit tightly with the grooves, disperse the force and prevent the bolts from rotating. They can keep the parts fixed and reduce equipment failures.