Flat countersunk head square neck bolts

Send Inquiry

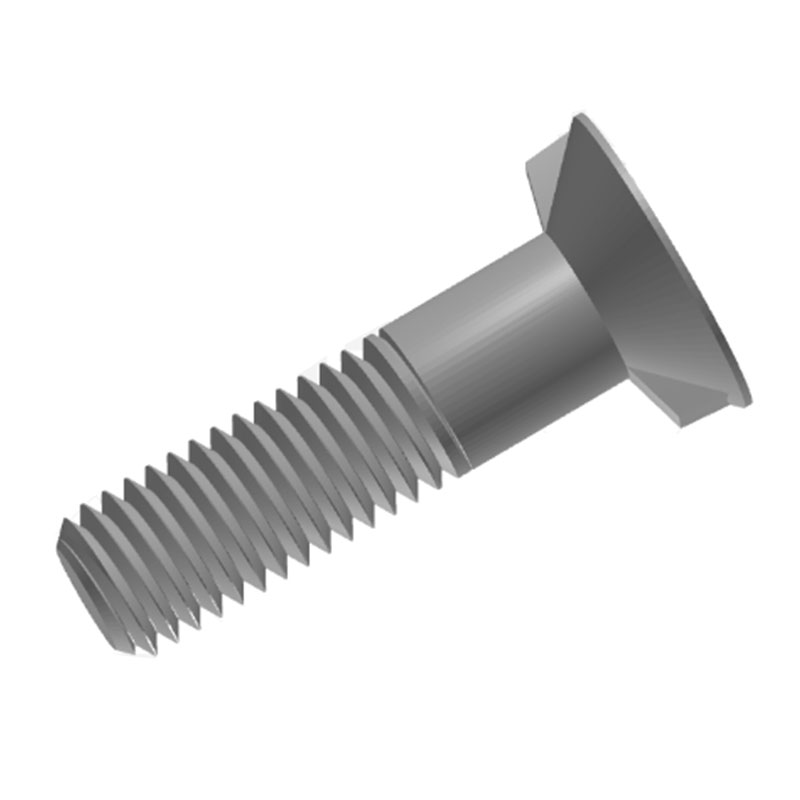

The head of the Flat countersunk head square neck bolts is flat and can sink completely into the material. After installation, the surface looks particularly flat without any protrusions. Below is a square neck, and further down is a threaded screw.

Product details

This can fix the steel grating steps to the longitudinal beams. During the installation process, the square neck will be locked in the slot of the longitudinal beam. Only one worker needs to tighten the nut below, and the bolt can remain stationary. Its head is flush with the tread surface, eliminating the risk of foot pinching on industrial stairs.

Flat countersunk head square neck bolts are used to fix the side guide plates of conveyors. If you need to install wear-resistant strips on the frame of the mining conveyor, then you can choose them. They can cope with abrasive environments and resist rotation caused by vibration. They can prevent materials from getting stuck and ensure the smooth operation of the conveyor belt.

They can be used for assembling the panels of industrial ovens. They can withstand thermal cycles. During the assembly process, the bolts are fixed in the frame grooves to prevent the gaskets from rotating when they need to be compressed. The bolts are easy to clean internally, will not cause grease retention, and will not interfere with the airflow.

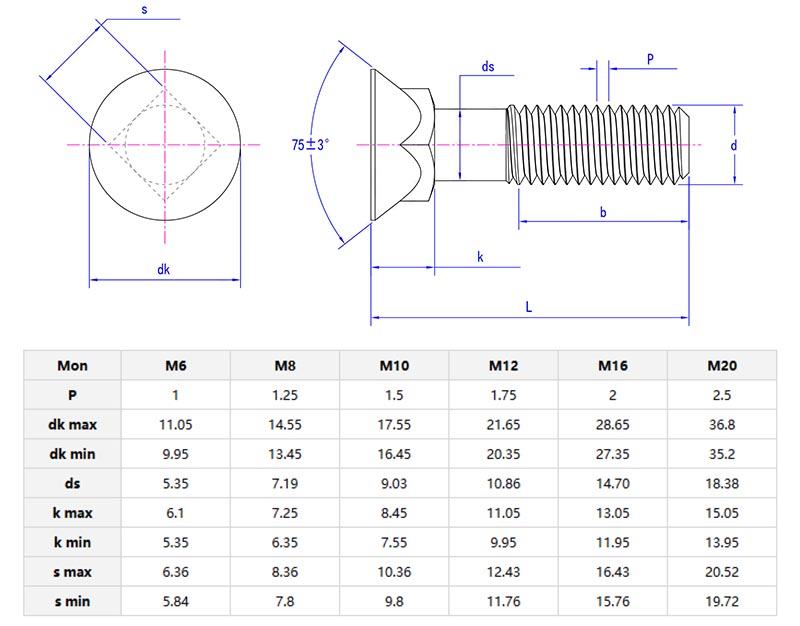

Product parameters

Product selling point

The greatest advantage of Flat countersunk head square neck bolts is that they are "installed flat and firmly". There are no protruding parts on the surface, so it is not afraid of scratching people or catching things, such as the surface of furniture or the casing of electronic devices. The square neck can be clamped into the pre-opened square hole. When tightening the nut, the bolt will not rotate along with it. The installation is particularly convenient and it is not easy to loosen.