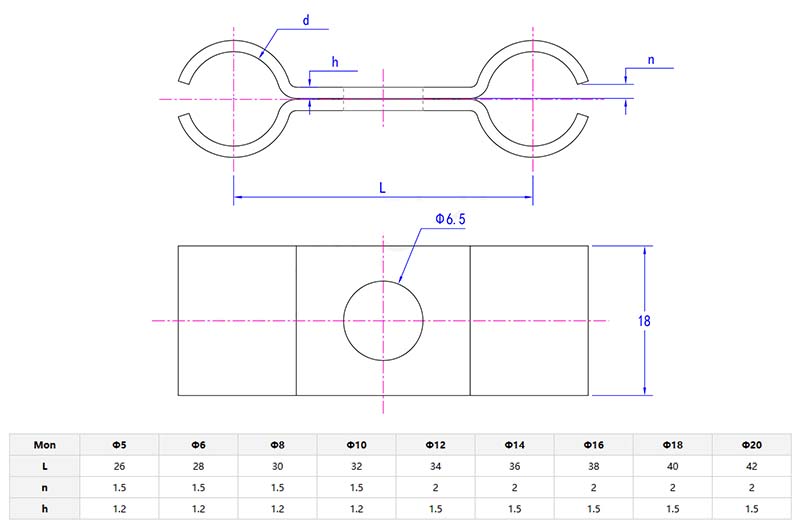

Double Tube Fixing Clamp

Send Inquiry

Double Tube Fixing Clamp is basically specialized fasteners made to spread out weight and keep things steady. They’ve got two matching clamping spots that mirror each other around a central line. These durable parts are great for situations where you need even pressure and connections that stay tight and stand up to vibration. They’re a straightforward way to join pipes, tubes, structural pieces, or mount equipment in lots of industrial and construction jobs—they just work consistently, even when under stress.

Product details

The main thing about Double Tube Fixing Clamp is how balanced they are designed. This symmetry makes sure the pressure is spread evenly across both clamping spots. With single-point or uneven clamps, parts might bend or get stressed unevenly, but these clamps avoid that. When the force is even, they hold things more securely, cut down on the chance of slipping, and don’t wear down the material in one spot as much. That means both the clamp and the thing it’s holding will last longer.

Product parameters

FAQ

Q: How does the symmetrical design of Double Tube Fixing Clamp improve installation safety and stability compared to standard clamps?

A: Balanced designs distribute the tightening force evenly on both sides of the pipe or object. This reduces the possibility of slippage or rotation during installation or use. Compared to uneven designs, this balanced design can fix objects more firmly and stably, making it safer - especially in complex piping systems where vibration or thermal changes may be present. It keeps everything aligned and avoids problems like misalignment or potential hazards that can happen with unbalanced clamps.