Double Stacked Self Locking Washer

Send Inquiry

The double stacked self locking washer comes with surface treatments like electro-galvanizing, hot-dip galvanizing, or passivation. These coatings help prevent rust, make installation smoother by reducing friction, and let the washer last longer in wet or acidic places.

Xiaoguo® factory provides a variety of layer options, and can also customize Double Layer Self Locking Washers, for example, black oxide if you want it to match the machine’s appearance, or dacromet coatings for high-temperature situations. Each treatment is picked to meet specific industry standards while keeping the washer’s locking ability strong.

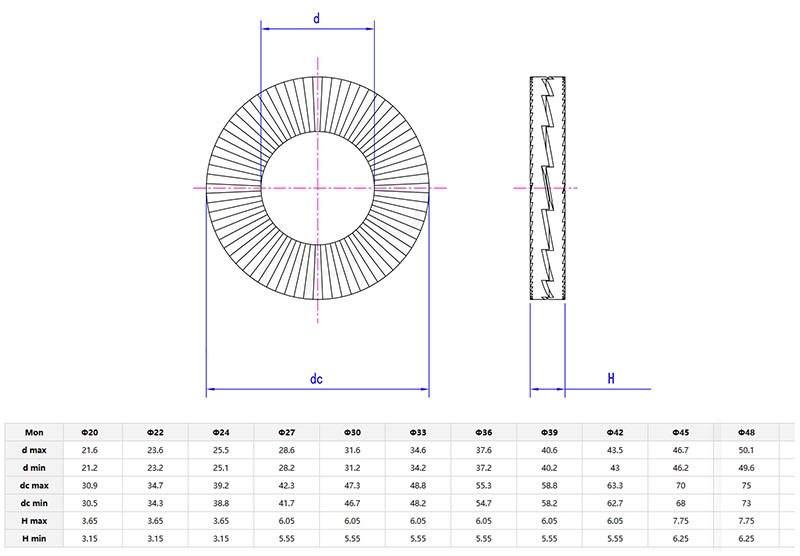

Size And Features

The double stacked self locking washer has both metric and imperial sizes. Metric sizes run from M5 to M20, and imperial sizes from 1/4 inch to 3/4 inch. Thickness is between 1.5mm and 4mm. If you’ve got a special project, you can get custom sizes to work with different bolt grades, like Grade 8 or 10.9.

The double-layer self-locking Washer is built small, so it fits in tight spots but still spreads weight evenly. The tech sheets list stuff like torque specs, temperature limits (-50°C to +300°C), and how much weight it can handle. That helps when you need to add it to mechanical designs correctly.

Application

Q: In which applications is the double Layer Self Locking Washer most effective?

A: The double stacked self locking washer is made for situations with a lot of vibration or moving loads, where regular fasteners usually don’t work. It’s used in places like car engine parts, airplane assemblies, heavy machine bolts, and steel structure connections. It can keep the clamping force steady even when there’s repeated stress, which makes it really useful in conveyor systems, wind turbines, and railway setups. Plus, industries that need to take things apart often, like equipment that needs a lot of maintenance, like it because they can reuse it. Because this washer provides good metal-to-metal contact, it is also often used in electrical grounding systems to prevent arcing or loosening over time.