Dependable Clinching Nut

Send Inquiry

Compared to weld nuts, Dependable Clinching nuts don't cause heat distortion, change the metal's structure, damage coatings, or create fume risks. They're quicker to install and often stronger when used on thin sheets.

Versus cage nuts or PEM nuts, Our nut make a sturdier, more permanent connection that holds up better to vibrations. They don't need those complicated cage parts or depend on spring tension to work.

And unlike rivet nuts, you don't need access to the back side to install a Dependable Clinching nut. They usually have more strength against being pushed out and sit lower on the side where they're installed.

Product Details:

Dependable Clinching nuts offer a lot of value: they're fast to use, strong, reliable, save money, give more design options, and are better for the environment. They're a key part of modern sheet metal work.

What's coming next? Making them work with super strong steels and lighter alloys, pairing them with smart installation systems that check quality as you go, making smaller ones for electronics, and using more specialized coatings.The nut will keep being an important, evolving solution for making strong, efficient assemblies all over the world.

How it works?

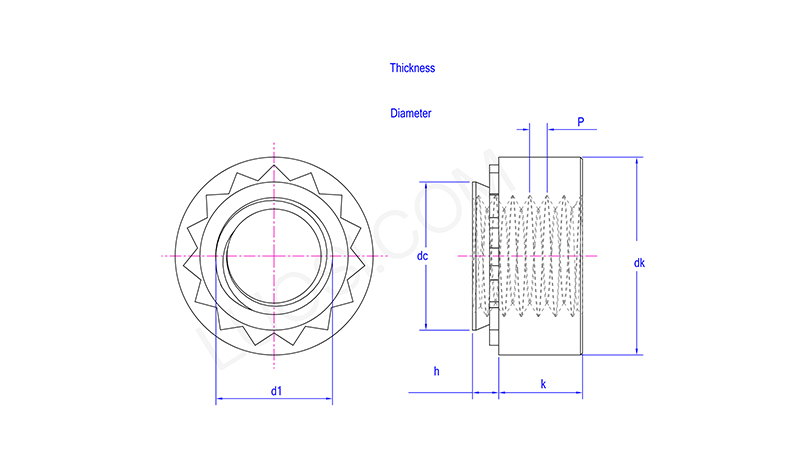

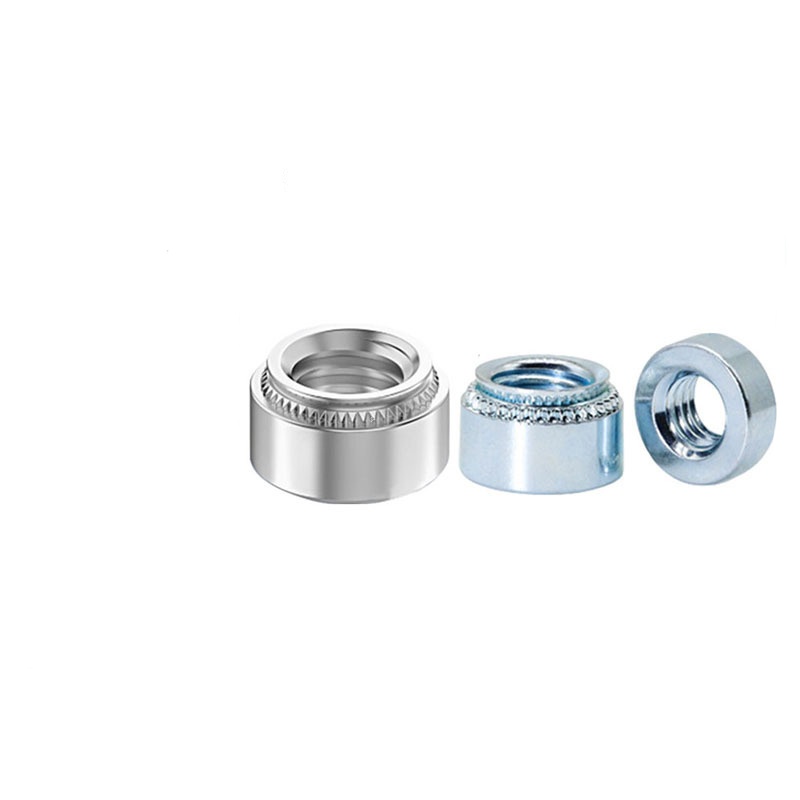

A Dependable Clinching nuts is a fastener that stays in place once installed, with a nut part already built in. Its base has little ridges or knurls. When you put it in, high pressure makes the sheet metal around it bend into those ridges. That creates a strong mechanical lock that holds up against vibrations. This cold-forming process means you don't need welding or glue.

| Mon | M2.5-2 | M3-0 | M3-1 | M3-2 | M3.5-0 | M3.5-1 | M3.5-2 | M4-0 | M4-1 | M4-2 | M5-0 |

| P | 0.45 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.7 | 0.7 | 0.7 | 0.8 |

| dc max | 4.2 | 4.2 | 4.2 | 4.2 | 4.73 | 4.73 | 4.73 | 5.38 | 5.38 | 5.38 | 6.33 |

| dk min | 6.05 | 6.05 | 6.05 | 6.05 | 6.85 | 6.85 | 6.85 | 7.65 | 7.65 | 7.65 | 8.45 |

| dk max | 6.55 | 6.55 | 6.55 | 6.55 | 7.35 | 7.35 | 7.35 | 8.15 | 8.15 | 8.15 | 8.95 |

| k min | 1.25 | 1.25 | 1.25 |

1.25 |

1.25 |

1.25 |

1.25 |

1.75 |

1.75 |

1.75 |

1.75 |

| k max | 1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

2.25 |

2.25 |

2.25 |

2.25 |

| h coder | 2 | 0 | 1 | 2 | 0 | 1 | 2 | 0 | 1 | 2 | 0 |

| h max | 1.38 | 0.77 | 0.97 | 1.38 | 0.77 | 0.97 | 1.38 | 0.77 | 0.97 | 1.38 | 0.77 |

|

Thickness of mounting plate min |

1.4 | 0.8 | 1 | 1.4 | 0.8 | 1 | 1.4 | 0.8 | 1 | 1.4 | 0.8 |

|

Diameter of mounting holes min |

4.22 |

4.22 |

4.22 |

4.22 |

4.75 |

4.75 |

4.75 |

5.41 |

5.41 |

5.41 |

6.35 |

|

Diameter of mounting holes max |

4.3 |

4.3 |

4.3 |

4.3 |

4.83 | 4.83 | 4.83 | 5.49 | 5.49 | 5.49 | 6.43 |

| d1 | M2.5 | M3 | M3 | M3 | M3.5 | M3.5 | M3.5 | M4 | M4 | M4 | M5 |